Manufactured Items vs Bundles: Definitions, Examples, and BOM Usage

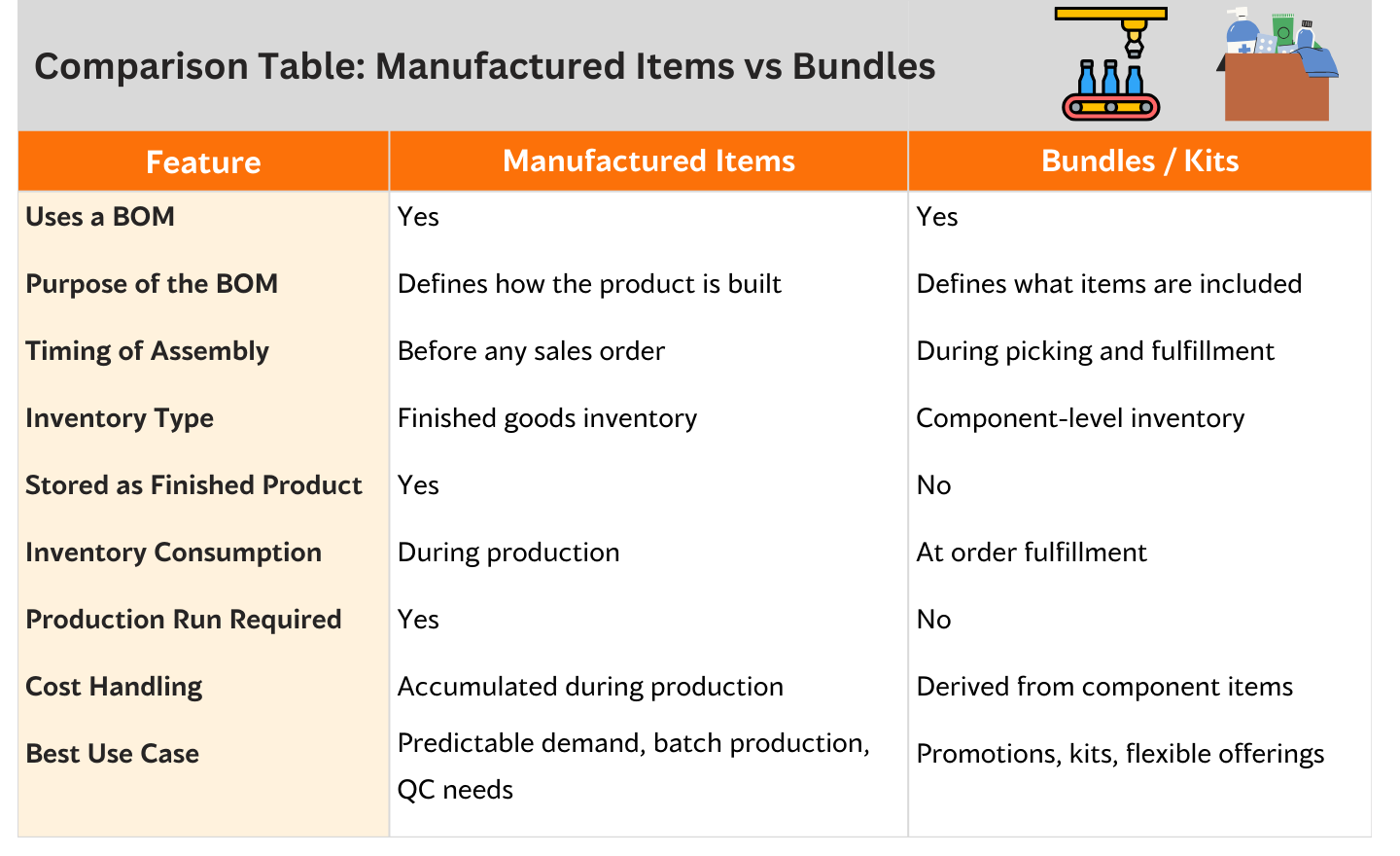

When configuring products in an inventory or ERP system, one of the most important distinctions to understand is the difference between manufactured items and bundles (or kits). Although both use a Bill of Materials (BOM), they differ in when assembly occurs, how inventory is tracked, and how orders are fulfilled.

Clearly defining these item types is essential for maintaining inventory accuracy, ensuring proper cost handling, and supporting efficient fulfillment as operations scale.

What Is a Manufactured Item?

A manufactured item is a product that is built in advance through a formal manufacturing or production process. The components listed in the BOM are consumed during production to create a finished good that is stocked as inventory before any customer order is placed.

Once manufacturing is complete, the item exists as its own SKU and is available for immediate picking, packing, and shipping.

Examples of Manufactured Items

- Prepared food products produced in batches

- Pre-assembled gift boxes built ahead of peak season

- Furniture assembled from multiple components

- Private-label products manufactured in advance

Manufactured items are best suited for products with predictable demand, longer lead times, or quality-control requirements that must be completed prior to sale.

What Is a Bundle or Kit?

A bundle or kit is a product that groups multiple existing items together for sale. While bundles also use a BOM to define which components are included, the individual items remain separate inventory products and are combined during order fulfillment.

When a sales order is placed, each component item is picked and shipped together as part of the bundle.

Examples of Bundles and Kits

- Promotional bundles combining multiple retail products

- Subscription boxes assembled per order

- Tool kits picked from individual tools

- Meal kits made from pre-packaged items

In this structure, the BOM functions as a sales and fulfillment definition, rather than a production recipe.

Although both structures rely on a BOM, they serve different operational purposes. Manufactured items use the BOM to drive production and create finished goods inventory, while bundles use the BOM to define how items are grouped and fulfilled.

This distinction affects inventory visibility, cost reporting, and how fulfillment workflows are executed.

Why This Distinction Matters

Choosing the correct item structure directly impacts:

- Inventory accuracy and real-time visibility

- Production planning and labor tracking

- Order fulfillment efficiency

- Cost accounting and financial reporting

- Overall operational performance

Defining items correctly upfront helps prevent costly adjustments as product catalogs and order volumes grow.

How Kechie Supports These Item Types

Kechie is designed to support both manufactured items and bundles by aligning system behavior with real-world operational processes. Manufactured items leverage BOMs to manage component consumption, production timing, and finished goods inventory, while bundles use BOMs to clearly define fulfillment requirements without altering underlying inventory structures.

By handling each item type according to how it is built and fulfilled, Kechie helps maintain accurate inventory records, reliable costing, and efficient workflows—giving businesses the flexibility to support both production-driven and fulfillment-driven product strategies within a single system.

Schedule a Free Demo Today!

See how Kechie ERP can transform your business, save you time, money, and aggravation. Click the button below to schedule your free demo.

Schedule Your Kechie Demo Now!