My Office Apps Launches AI Inventory Optimization for Kechie ERP

My Office Apps Launches AI Inventory Optimization for Kechie ERP

Irvine, Calif., March 3, 2026 /PR Newswire.com/ — My Office Apps (MOA), the company behind Kechie ERP, introduces new AI Inventory Optimization features within its Kechie ERP platform, delivering practical, results-focused innovation for modern inventory operations. These enhancements integrate advanced artificial intelligence directly into daily workflows, providing intelligent recommendations that support smarter operational decisions for inventory planning and real-time materials requirements planning (MRP).

Read more on PR Newswire

Inventory Management Software for Universities

Inventory Management for Universities, Stop Losing Track of Campus Assets

Walk across any university campus and you will see classrooms, labs, bookstores, IT departments, and facilities teams all operating at full speed.

What you do not see is the constant flow of equipment, supplies, and purchase requests happening behind the scenes.

Laptops are issued. Lab instruments are transferred. Maintenance parts are consumed. Departments submit purchase requests daily. Bookstores reorder seasonal inventory. Equipment moves between campuses.

If you oversee operations, IT, facilities, or procurement, you are responsible for more than inventory. You are responsible for what gets purchased, where it goes, and who is accountable for it.

Without structure, buying and tracking become disconnected. That is where inventory management software for universities becomes essential.

Universities Operate Like Small Cities

A typical institution manages:

• Laptops and tablets assigned to faculty and students

• Desktop computers and servers in labs

• Projectors and AV systems in lecture halls

• Scientific lab equipment and research instruments

• Facilities maintenance parts and MRO inventory

• Furniture and fixtures

• Bookstore inventory and course materials

• Department specific tools and specialty equipment

Now multiply that across dozens of departments and multiple campuses.

Without centralized university inventory management, simple questions become difficult:

Do we already have this item in stock?

Who approved this purchase?

Where is that equipment now?

Why are we reordering items that should be available?

Inventory and purchasing must work together. If they do not, institutions overspend and lose visibility.

Serialized Inventory Tracking, The Difference Between Quantity and Control

Tracking total quantities is not enough for higher education. High value campus assets require serialized inventory tracking.

Serialized tracking assigns a unique serial number to each individual asset. Instead of recording 200 laptops as a single quantity, you track each device independently.

For universities, this is critical for:

• IT equipment tracking for faculty and students

• Lab equipment accountability and compliance

• Asset assignment by department or individual

• Warranty and service history tracking

• Reducing lost or unreturned devices

• Supporting audit readiness

When someone leaves the university, you can see exactly which device was issued. When a lab instrument is repaired, you have a full documented history.

Kechie Inventory Management was built with inventory control at its core. Serialized items are tracked from receipt through assignment, transfer, repair, and retirement. Every movement is recorded in real time.

That level of traceability strengthens accountability across campus.

Procurement Is Part of the Control, Not a Separate Process

Many universities rely on district or institution mandated accounting systems. That does not mean procurement and buying should operate separately from inventory.

In practice, most inventory issues begin in purchasing.

Departments submit requests without knowing current stock levels. Items are ordered while identical products sit unused in another building. Emergency purchases happen because reorder points were not visible.

Kechie includes procurement management as part of the overall solution. Purchase requests, approvals, and purchase orders connect directly to inventory.

That means you can:

• Review available inventory before issuing a new purchase order

• Route department requests through structured approval workflows

• Receive items directly into inventory upon delivery

• Tie serialized assets to specific purchase records

• Track open purchase orders in real time

You are not replacing your required accounting system. You are strengthening operational control before and during the buying process.

The result is fewer duplicate purchases and clearer visibility into what is on order versus what is already in stock.

IT Equipment Buying and Lifecycle Visibility

Technology refresh cycles represent significant capital spend for universities.

Without centralized data, IT teams often purchase additional devices without reviewing existing availability or repair history.

With integrated inventory and procurement control, you can:

• Review serialized device counts before approving new purchases

• Track asset age and condition

• Monitor repair frequency

• Plan refresh cycles based on real usage data

Buying decisions become data driven instead of reactive.

Facilities and MRO Purchasing Control

Facilities teams frequently purchase maintenance parts and equipment under time pressure.

With multi warehouse visibility , facilities leaders can see inventory across buildings before ordering. Usage patterns help define reorder points. Serialized tracking supports high value equipment maintenance history.

This reduces emergency purchases and unnecessary overstock.

Bookstore and Academic Materials Management

Bookstores face seasonal demand swings. Ordering too much ties up budget. Ordering too little impacts students.

When purchasing is connected to real time inventory data, bookstores can:

• Order based on actual sell through rates

• Transfer stock between locations

• Control high value electronics with serialized tracking

Inventory and procurement working together reduces waste and improves planning.

Centralized Inventory Control That Supports the Mission

Universities exist to educate students and support research. Poor inventory and purchasing processes quietly drain resources from that mission.

When you can see what is in stock, what is on order, and who is responsible for each serialized asset, decisions improve.

Kechie provides cloud based inventory management with integrated procurement capabilities, built around real time data visibility. Serialized assets, multi campus inventory, and structured purchasing workflows operate in one connected system.

For operations leaders, the benefits are practical:

• Fewer duplicate purchases

• Stronger department accountability

• Real time campus wide visibility

• Reduced asset loss

• Better control over capital equipment

If you are evaluating inventory management software for universities, focus on this:

Can you see, in real time, exactly what you own and what you are about to buy?

If not, it may be time to replace disconnected processes with a centralized higher education inventory management system built for accountability.

See how Kechie can help your campus gain control over serialized assets and purchasing. Book a 20 minute ERP evaluation call and assess where your current process is costing you time, equipment, and operational clarity.

Schedule a Free Demo Today!

See how Kechie ERP can transform your business, save you time, money, and aggravation. Click the button below to schedule your free demo.

Schedule Your Kechie Demo Now!In This Article

-Universities Operate Like Small Cities

-Serialized Inventory Tracking, The Difference Between Quantity and Control

-Procurement Is Part of the Control, Not a Separate Process

-IT Equipment Buying and Lifecycle Visibility

-Facilities and MRO Purchasing Control

-Bookstore and Academic Materials Management

-Centralized Inventory Control That Supports the Mission

Related Articles

Cloud ERP for Manufacturing Companies

What is an ERP system, and how is it used?

There’s a point in nearly every growing manufacturing or distribution business when the cracks begin to show.

Inventory doesn’t match across locations.

Sales promises a ship date production can’t meet.

Finance closes the month and finds margin gaps no one expected.

The team is working hard. The problem isn’t effort — it’s fragmentation. Systems don’t communicate, data lives in silos, and decisions rely on incomplete information. That’s typically when companies begin exploring a cloud ERP solution.

But before evaluating vendors, it helps to answer the core question clearly:

What is an ERP system, and how is ERP software actually used in a real operation?

What Is an ERP System?

An ERP system, short for Enterprise Resource Planning, is software that centralizes your core business functions into one connected platform.

Instead of operating with:

- Accounting in one system

- Inventory management software in another

- CRM disconnected from operations

- Production planning in spreadsheets

- Purchasing managed through email

An ERP system integrates everything.

- One database.

- One workflow.

- One real-time source of truth.

When a sales order is entered, inventory updates immediately. Material Requirements Planning (MRP) recalculates demand. Production schedules adjust. Financial projections reflect the impact instantly.

ERP software connects departments that typically operate in silos. That connection is what removes operational friction.

Why Growing Companies Move to Cloud ERP

Most companies do not start with ERP software. They grow into needing one.

Early on, accounting software and spreadsheets work.

But growth adds complexity:

- More SKUs

- More customers

- More warehouses

- More vendors

- More compliance requirements

As complexity increases, disconnected tools become bottlenecks. Inventory discrepancies rise. Production planning turns reactive. Purchasing responds to shortages instead of anticipating them. Sales data fails to align with operational capacity

This is where a scalable ERP becomes essential.

Cloud ERP for manufacturing companies solves this by centralizing data and making it accessible in real time across departments and facilities.

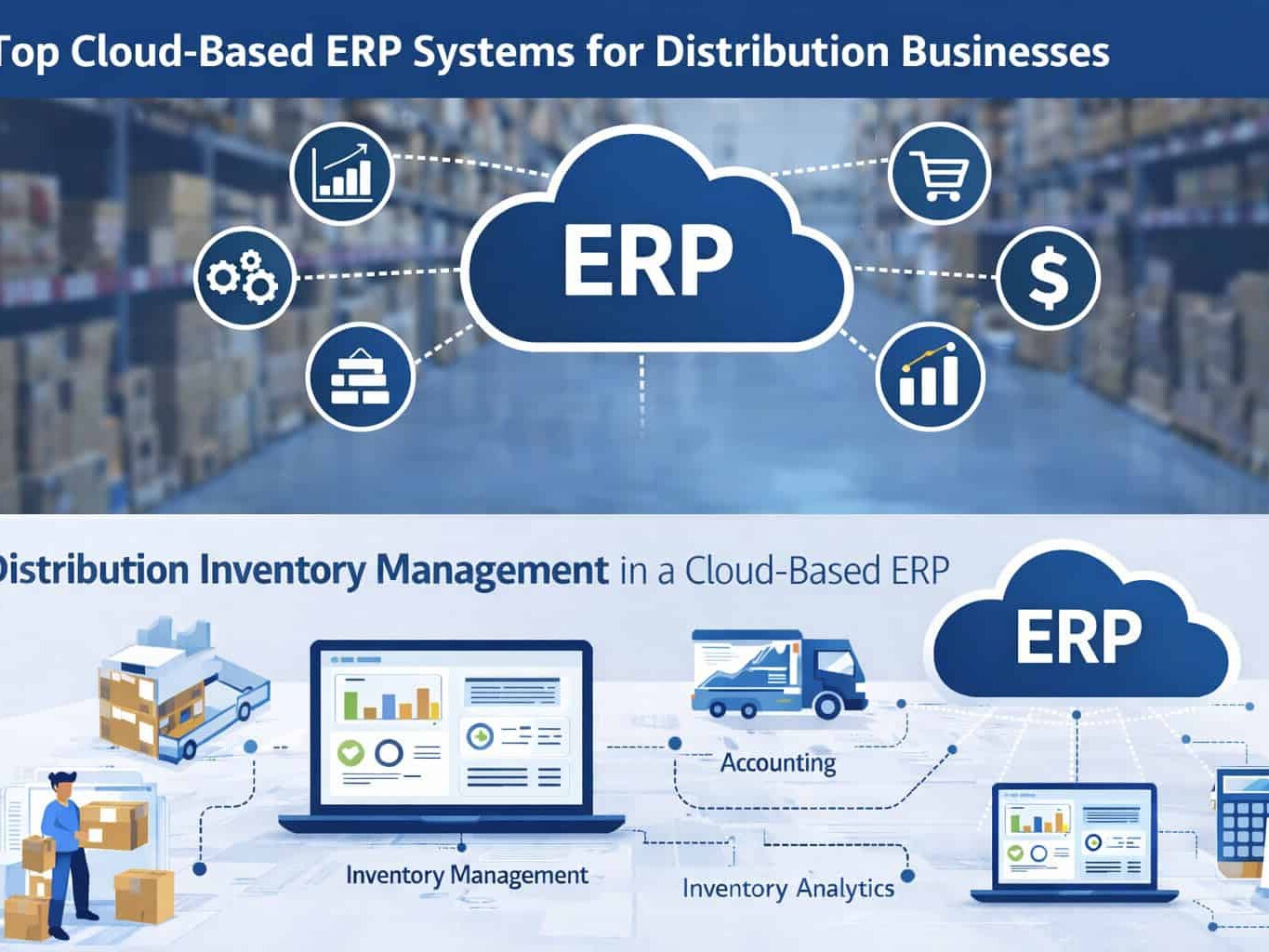

How Is ERP Software Used in Manufacturing and Distribution?

Let’s move from theory to application.

Here’s how a manufacturing ERP system functions day to day.

Inventory Management: The Foundation

In manufacturing and distribution, inventory is the operational backbone.

A cloud ERP for manufacturing companies includes advanced inventory management software that allows you to:

- Track multi-warehouse inventory in real time

- View available, committed, and incoming quantities

- Manage lot and serial tracking

- Automate reorder points

- Reduce overstock and stockouts

For ERP for distributors, this ensures accurate fulfillment across locations.

For manufacturers, this ensures raw materials and finished goods remain synchronized with production schedules.

When inventory lives inside a connected ERP system, data flows automatically to purchasing, production, CRM, and finance. This synchronization protects margins and improves fulfillment accuracy.

Manufacturing and Production Planning

A manufacturing ERP system connects shop floor operations directly to demand.

ERP software enables:

- Bills of materials management

- MRP calculations

- Work center scheduling

- Labor and material cost tracking

- Real-time production monitoring

Rather than reacting to shortages, MRP forecasts material requirements. Instead of guessing capacity, you see workload across work centers. A cloud ERP for manufacturing companies ensures this visibility across multiple facilities without infrastructure burden.

Purchasing and Supply Chain

Without ERP software, purchasing often operates in reaction mode.

With ERP implementation:

- MRP identifies shortages before they occur

- Reorder thresholds trigger automatically

- Vendor performance becomes measurable

- Purchasing aligns with forecasted demand

This shifts procurement from firefighting to strategic planning. ERP for distributors especially benefits here, as supply chain complexity increases with scale.

CRM: Aligning Sales With Operations

Customer relationship management is frequently isolated from operational systems. In a unified ERP environment, CRM connects directly to inventory, production, and finance.

An ERP system with built-in CRM allows you to:

- Track open quotes and sales pipelines

- View customer order history

- Monitor payment behavior

- Analyze buying trends

- Manage returns and service cases

When CRM is embedded inside ERP software:

Sales cannot overpromise capacity.

Operations see demand trends early.

Finance forecasts revenue accurately.

Alignment improves performance.

Order Management: From Quote to Cash

Here’s what synchronization looks like in practice.

A large order enters the ERP system.

Inventory allocates automatically.

MRP recalculates material demand.

Production schedules adjust.

Purchasing receives shortage alerts.

Finance sees revenue impact instantly.

Without ERP software, this requires emails, calls, and manual checks. With a cloud ERP for manufacturing companies, it happens in seconds.

Financial Management: Real-Time Control

ERP software integrates financial management directly into operations.

It supports:

- Accounts payable

- Accounts receivable

- General ledger

- Revenue recognition

- Margin analysis by SKU and customer

Because operational data and financial data live inside the same ERP system, reporting reflects reality.

Not estimates.

Not delayed consolidations.

Real-time insight.

ERP vs Accounting Software

This is a common misconception.

Accounting software answers:

What happened financially?

An ERP system answers:

What is happening operationally right now?

Accounting records transactions.

ERP software manages the business.

For ERP for small to midsize businesses, the shift usually occurs when operational complexity exceeds accounting capabilities.

When Is It Time for ERP Implementation?

You may need ERP implementation if:

- Inventory discrepancies are frequent

- Reporting requires manual consolidation

- Production planning is reactive

- CRM is disconnected from operations

- Growth is stressing systems

- Multi-warehouse operations lack visibility

ERP implementation becomes necessary when fragmentation limits performance.

Cloud ERP vs On-Premise ERP

On-premise ERP requires internal servers and maintenance.

Cloud ERP software:

- Runs in a browser

- Updates automatically

- Scales easily

- Reduces IT overhead

For manufacturers and distributors expanding operations, cloud ERP provides flexibility without infrastructure burden.

The Real ROI of a Cloud ERP for Manufacturing Companies

ERP implementation is not about adding technology.

It’s about eliminating inefficiencies.

Companies adopting a scalable ERP often see:

- Lower inventory carrying costs

- Improved forecast accuracy

- Reduced fulfillment errors

- Faster month-end close

- Better cross-department alignment

- Increased customer retention

For operations leaders, ERP software delivers clarity.

Clarity reduces risk.

Reduced risk improves margins.

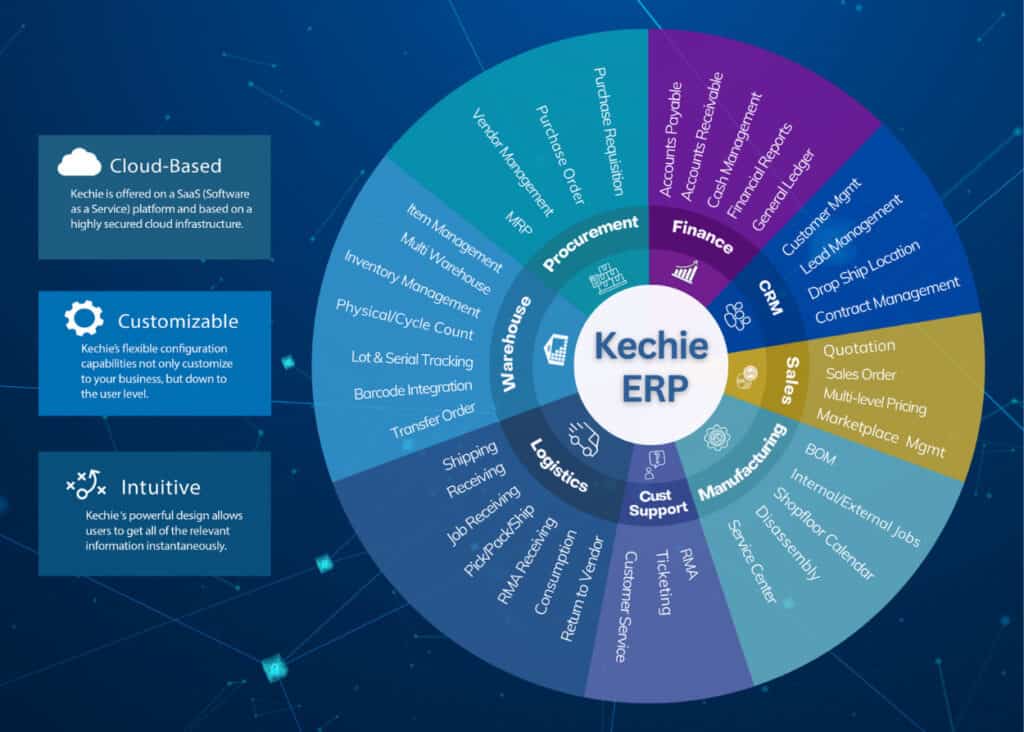

Where Kechie ERP Fits

If you are evaluating cloud ERP for manufacturing companies or ERP for distributors, operational fit matters.

Kechie ERP was built specifically for manufacturers and distributors that require:

- Real-time multi-warehouse inventory management

- Integrated manufacturing ERP system capabilities

- Built-in CRM connected to operations

- Automated financial reporting

- Scalable cloud ERP architecture

Kechie ERP centralizes inventory management software, CRM, production planning, purchasing, and finance into one unified ERP system.

Not stitched modules.

Not fragile integrations.

A connected foundation built for growth.

Ready to See How It Works?

If your organization is experiencing:

- Inventory visibility issues

- Production planning bottlenecks

- Disconnected CRM and operations

- Manual reporting burdens

It may be time to evaluate a cloud ERP for manufacturing companies.

Schedule a Free Demo Today!

See how Kechie ERP can transform your business, save you time, money, and aggravation. Click the button below to schedule your free demo.

Schedule Your Kechie Demo Now!In This Article

-How Is ERP Software Used in Manufacturing and Distribution?

-Inventory Management: The Foundation

-Manufacturing and Production Planning

-Purchasing and Supply Chain

-CRM: Aligning Sales With Operations

-Order Management: From Quote to Cash

-Financial Management: Real-Time Control

-ERP vs Accounting Software

-When Is It Time for ERP Implementation?

-Cloud ERP vs On-Premise ERP

-The Real ROI of a Cloud ERP for Manufacturing Companies

-Where Kechie ERP Fits

Related Articles

Manufactured Items vs Bundles

Manufactured Items vs Bundles: Definitions, Examples, and BOM Usage

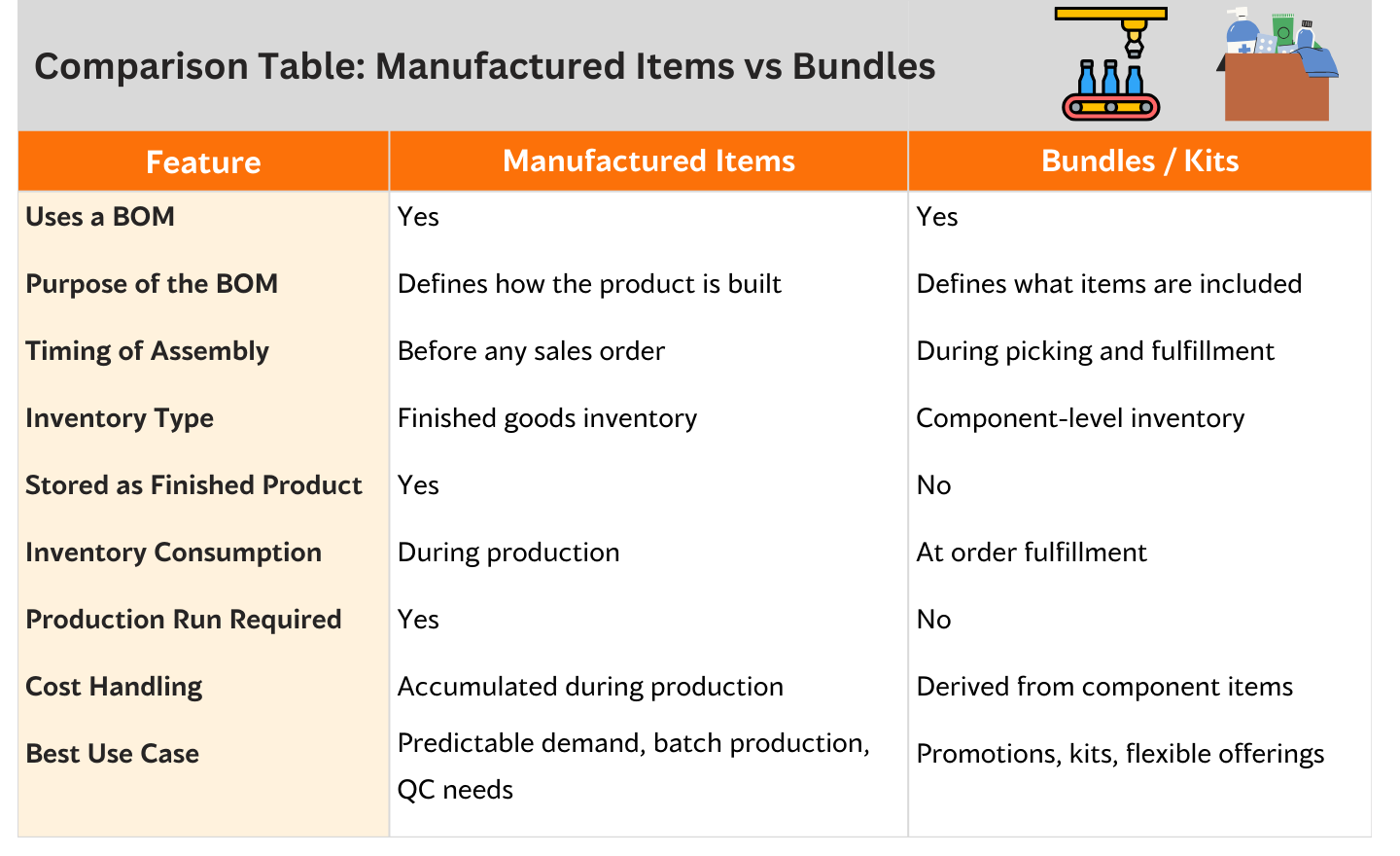

When configuring products in an inventory or ERP system, one of the most important distinctions to understand is the difference between manufactured items and bundles (or kits). Although both use a Bill of Materials (BOM), they differ in when assembly occurs, how inventory is tracked, and how orders are fulfilled.

Clearly defining these item types is essential for maintaining inventory accuracy, ensuring proper cost handling, and supporting efficient fulfillment as operations scale.

What Is a Manufactured Item?

A manufactured item is a product that is built in advance through a formal manufacturing or production process. The components listed in the BOM are consumed during production to create a finished good that is stocked as inventory before any customer order is placed.

Once manufacturing is complete, the item exists as its own SKU and is available for immediate picking, packing, and shipping.

Examples of Manufactured Items

- Prepared food products produced in batches

- Pre-assembled gift boxes built ahead of peak season

- Furniture assembled from multiple components

- Private-label products manufactured in advance

Manufactured items are best suited for products with predictable demand, longer lead times, or quality-control requirements that must be completed prior to sale.

What Is a Bundle or Kit?

A bundle or kit is a product that groups multiple existing items together for sale. While bundles also use a BOM to define which components are included, the individual items remain separate inventory products and are combined during order fulfillment.

When a sales order is placed, each component item is picked and shipped together as part of the bundle.

Examples of Bundles and Kits

- Promotional bundles combining multiple retail products

- Subscription boxes assembled per order

- Tool kits picked from individual tools

- Meal kits made from pre-packaged items

In this structure, the BOM functions as a sales and fulfillment definition, rather than a production recipe.

Although both structures rely on a BOM, they serve different operational purposes. Manufactured items use the BOM to drive production and create finished goods inventory, while bundles use the BOM to define how items are grouped and fulfilled.

This distinction affects inventory visibility, cost reporting, and how fulfillment workflows are executed.

Why This Distinction Matters

Choosing the correct item structure directly impacts:

- Inventory accuracy and real-time visibility

- Production planning and labor tracking

- Order fulfillment efficiency

- Cost accounting and financial reporting

- Overall operational performance

Defining items correctly upfront helps prevent costly adjustments as product catalogs and order volumes grow.

How Kechie Supports These Item Types

Kechie is designed to support both manufactured items and bundles by aligning system behavior with real-world operational processes. Manufactured items leverage BOMs to manage component consumption, production timing, and finished goods inventory, while bundles use BOMs to clearly define fulfillment requirements without altering underlying inventory structures.

By handling each item type according to how it is built and fulfilled, Kechie helps maintain accurate inventory records, reliable costing, and efficient workflows—giving businesses the flexibility to support both production-driven and fulfillment-driven product strategies within a single system.

Schedule a Free Demo Today!

See how Kechie ERP can transform your business, save you time, money, and aggravation. Click the button below to schedule your free demo.

Schedule Your Kechie Demo Now!Related Articles

Outgrowing QuickBooks? When a Full ERP Makes More Sense

Outgrowing QuickBooks? When a Full ERP Makes More Sense

When It’s Time to Move Beyond QuickBooks — and What a Full ERP Really Solves

QuickBooks is often the first accounting system a business adopts — and for good reason. It’s accessible, familiar, and works well in the early stages.

But for many growing companies, there comes a point where the question isn’t “How do we upgrade QuickBooks?”

It’s “Why are we still building so many workarounds around it?”

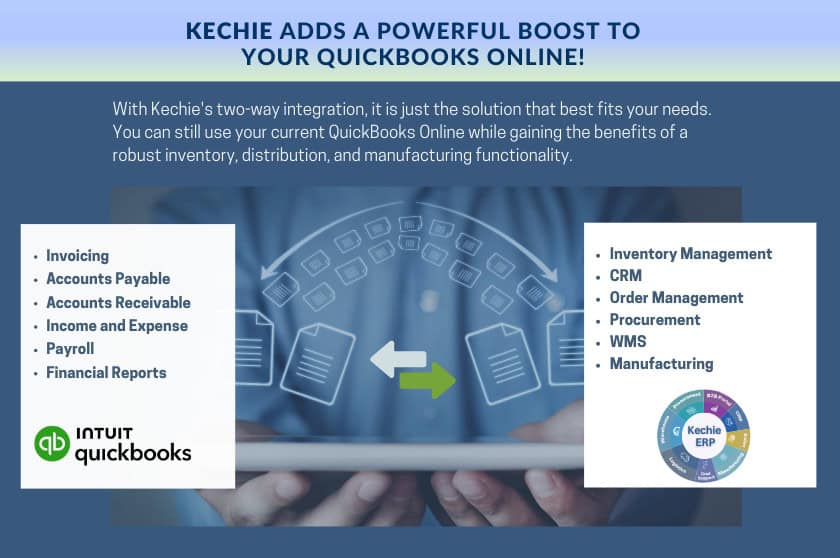

As QuickBooks Desktop continues to be phased out and more users are pushed toward QuickBooks Online, some businesses realize that simply moving accounting to the cloud doesn’t solve their bigger operational challenges. That’s usually the moment ERP enters the conversation.

What Actually Pushes Businesses Beyond QuickBooks

Most companies don’t leave QuickBooks because they dislike it.

They leave because the business outgrows what accounting software alone can support.

Common signals include:

- Inventory tracked across spreadsheets and disconnected tools

- Orders, fulfillment, and purchasing handled outside accounting

- Multiple locations or warehouses with limited visibility

- Manual reconciliation between sales, inventory, and finance

- Leadership questioning whether reports reflect reality

QuickBooks didn’t fail — it just wasn’t designed to be the operational backbone of a growing business.

Why Moving to QBO Isn’t Always Enough

For many businesses, QuickBooks Online (QBO) is a logical next step — and for accounting-only needs, it works well.

But when inventory, operations, and reporting are central to the business, QBO often highlights the same gaps Desktop had:

- Limited inventory depth

- Minimal workflow automation

- Disconnected operational processes

At that point, businesses face a choice:

- Continue extending QuickBooks with more systems

- Or consolidate into a single platform designed to manage operations and accounting together

This is where a full ERP becomes a serious consideration.

What a Full ERP Actually Does (Without the Buzzwords)

ERP doesn’t have to be complicated.

At its core, a full ERP brings accounting, inventory, operations, and reporting into one system with a single source of truth.

Instead of syncing data between tools, teams work from real-time information across:

- Accounting and financials

- Inventory and purchasing

- Orders and fulfillment

- Customer and operational data

For growing businesses, this reduces friction, manual work, and data inconsistencies.

When a Full ERP Makes Sense

A full ERP is usually the right move when:

- Inventory accuracy directly impacts revenue or customer experience

- Operations involve multiple steps, locations, or teams

- Reporting delays slow decision-making

- Manual processes are limiting growth

- Integrations and workarounds are becoming difficult to manage

At this stage, extending QuickBooks can feel like maintaining complexity instead of reducing it.

ERP Doesn’t Have to Mean “Enterprise-Only”

One of the biggest misconceptions about ERP is that it’s only for very large companies.

Modern ERPs are built for growing, mid-market businesses that need:

- Advanced inventory and operations

- Built-in accounting

- Flexibility without enterprise bloat

- Faster implementations and lower overhead

For many companies, ERP isn’t about adding complexity — it’s about removing it.

How Businesses Typically Get Here

Most companies don’t wake up one day and decide to replace QuickBooks.

They get there gradually — after layering spreadsheets, apps, and workarounds on top of accounting software that was never meant to run the entire business.

By the time ERP enters the conversation, the real goal is usually clarity:

fewer systems, better visibility, and less manual work.

👉 Related reading:

• QuickBooks Desktop Is Being Phased Out — What Growing Businesses Should Do Next

• Why So Many Businesses Are Moving from QuickBooks Desktop to QuickBooks Online — and Where QBO Needs Help

Schedule a Free Demo Today!

See how Kechie ERP can transform your business, save you time, money, and aggravation. Click the button below to schedule your free demo.

Schedule Your Kechie Demo Now!Related Articles

QuickBooks Desktop to QBO: What Works — and Where QBO Falls Short

QuickBooks Desktop to QBO: What Works — and Where QBO Falls Short

Why So Many Businesses Are Moving from QuickBooks Desktop to QuickBooks Online — and Where QBO Needs Help

As QuickBooks Desktop continues to be phased out, many businesses are finding themselves pointed in one direction: QuickBooks Online (QBO).

Desktop is no longer being sold as a long-term solution, multiple Desktop versions have already been sunset, and the remaining versions are approaching end of support — including QuickBooks Desktop 2023 in May 2026. Intuit’s direction is clear: QuickBooks Online is the future.

For many businesses, QBO feels like the natural next step. But moving to QBO raises an important question:

How do you move forward without rebuilding the same workarounds you relied on with Desktop?

Why QuickBooks Online Is Often the First Step

QuickBooks Online is where Intuit is investing. It offers:

- Cloud access from anywhere

- Automatic updates and security patches

- Easier collaboration across teams

- Ongoing product support

For core accounting, QBO does exactly what it’s designed to do.

If accounting is your only challenge and inventory is minimal, QBO may be all you need.

Where QuickBooks Online Starts to Fall Short

QuickBooks Online was designed first and foremost as an accounting platform.

As businesses grow, limitations tend to show up around:

- Inventory beyond the basics

- Multiple locations or warehouses

- Order and fulfillment workflows

- Operational visibility and automation

These are often the same areas where Desktop users relied on spreadsheets, add-ons, and manual processes.

Rather than forcing QBO to do more than it was designed for, many businesses pair it with a robust inventory and operations system.

In this setup:

- QuickBooks Online remains the system of record for accounting

- Inventory and workflows are handled outside accounting

- Data stays synced without duplicate entry

This allows teams to modernize operations without disrupting finance.

👉 Related reading:

QuickBooks Desktop Is Being Phased Out — What Growing Businesses Should Do Next

Schedule a Free Demo Today!

See how Kechie ERP can transform your business, save you time, money, and aggravation. Click the button below to schedule your free demo.

Schedule Your Kechie Demo Now!Related Articles

QuickBooks Desktop Is Being Phased Out: What Growing Businesses Should Do

QuickBooks Desktop Is Being Phased Out: What Growing Businesses Should Do

QuickBooks Desktop is being phased out — What That Really Means for Growing Businesses

If you’re a business owner, one of the first pieces of software you look for to run your business is an accounting system. And let’s face it — QuickBooks is usually the first name that comes up. It’s the biggest player in the SMB accounting market, it’s relatively simple to set up, and it’s easy for teams to learn and use.

For many companies, QuickBooks Desktop (including Enterprise) has done exactly what it was meant to do in the early stages: manage the books, keep things organized, and support day-to-day operations without much friction.

But businesses don’t stay small forever. As operations grow more complex and expectations increase, systems that once worked well can start to feel limiting. And now, with QuickBooks Desktop no longer being sold as a long-term solution, many Desktop versions have already been sunset, and Intuit’s direction is clear: all QuickBooks users are being pushed toward QuickBooks Online (QBO).

Many growing companies are reaching a natural decision point — not because QuickBooks failed them, but because they’ve outgrown what Desktop was designed to handle.

When Is QuickBooks Desktop 2023 Being Discontinued?

QuickBooks Desktop 2023 will reach end of support in May 2026. After that date, Intuit will no longer provide:

• Security updates or patches

• Technical support

• Online services like payroll, bank feeds, and integrations

While the software may still open, it will be unsupported. For businesses that rely on accurate financials, inventory visibility, or compliance, running core operations on unsupported software introduces real risk over time.

Can You Keep Using QuickBooks Desktop After May 2026?

Technically, yes — but practically, it becomes risky very quickly.

Once support ends, even small issues can snowball. Integrations stop syncing, updates no longer install cleanly, and manual workarounds start creeping in. Most companies don’t realize how dependent they are on Desktop until it begins slowing everything else down.

For growing teams, unsupported software often becomes a hidden bottleneck.

Why This Impacts QuickBooks Enterprise Users More Than Others

Enterprise users typically rely on QuickBooks for much more than basic bookkeeping.

Many are managing:

• Multiple warehouses or locations

• Inventory that needs to be accurate, not “close enough”

• High transaction volumes

• Reporting leadership depends on

To keep Desktop working, teams often layer on spreadsheets, add-ons, and manual processes. It works — until it doesn’t.

The sunset forces an honest question:

Are you running your business, or are you working around your system?

What Are Growing Businesses Doing Instead?

As May 2026 approaches, most QuickBooks Enterprise users find themselves evaluating one of two realistic paths.

Path 1: Move to QuickBooks Online — and Decide How Much More You Actually Need

For businesses that want to stay in the QuickBooks ecosystem, QuickBooks Online (QBO) is often the next step. It offers cloud access, automatic updates, and continued support.

If accounting is your only real challenge, and you don’t rely heavily on inventory, orders, or operational workflows, then moving to QBO may be all you need.

For growing businesses, however, accounting is usually just one piece of the puzzle. As inventory, fulfillment, and operations become more complex, many teams realize that QBO alone doesn’t replace the workarounds they relied on in Desktop.

That’s why many businesses choose to move to QuickBooks Online with a robust inventory and operations platform — keeping QuickBooks for accounting, while managing inventory, orders, and workflows in a system built for scale.

👉 Related reading:

Why So Many Businesses Are Moving from QuickBooks Desktop to QuickBooks Online — and Where QBO Needs Help

Path 2: Move Beyond QuickBooks Entirely

For other businesses, the sunset is an opportunity to simplify.

Instead of managing accounting, inventory, CRM, and reporting across multiple systems, they move to a single cloud platform that brings everything together — including accounting.

👉 Related reading:

When It’s Time to Replace QuickBooks with a Full Cloud ERP

Schedule a Free Demo Today!

See how Kechie ERP can transform your business, save you time, money, and aggravation. Click the button below to schedule your free demo.

Schedule Your Kechie Demo Now!In This Article

-When Is QuickBooks Desktop 2023 Being Discontinued?

-Can You Keep Using QuickBooks Desktop After May 2026?

-Why This Impacts QuickBooks Enterprise Users More Than Others

-What Are Growing Businesses Doing Instead?

-Path 1: Move to QuickBooks Online

-Path 2: Move Beyond QuickBooks Entirely

Related Articles

What Is Product Variation?

What Is Product Variation?

Product variation refers to managing multiple versions of the same base product using defined attributes rather than creating separate, disconnected items.

Each unique combination of attributes creates a variant, which can be tracked independently for inventory, purchasing, manufacturing, and fulfillment.

Common Product Variation Attributes

| Size | Finish |

| Color | Configuration |

| Gender | Length, weight, or capacity |

| Material | Packaging or bundle type |

Variation allows businesses to offer flexibility to customers while maintaining operational control in ERP systems.

Why Product Variation Is Essential in ERP Inventory Management

Variation exists because real-world inventory decisions happen at the variant level, not the product level.

Without proper variation modeling, businesses experience:

- Stockouts in specific sizes or colors

- Over-purchasing of slow-moving variants

- Inaccurate inventory valuation

- Fulfillment and picking errors

- Weak demand forecasting

ERP inventory management systems rely on variation to ensure accuracy, traceability, and scalability.

Managing Inventory Without Part Numbers Using Variations

Many businesses begin operations without standardized part numbers or SKUs. This is common in:

- Apparel and fashion

- Furniture and home goods

- Custom manufacturing

- Contract production

- Early-stage or fast-growing companies

Parent Item + Variation Model

ERP systems like Kechie address this using a parent item with variation attributes.

How This Works in Practice

- A base (parent) item represents the generic product

- Variation attributes define differences (size, color, gender, etc.)

- Inventory is tracked at the variant level

- Formal SKUs or part numbers can be introduced later

This approach allows businesses to operate immediately while maintaining inventory visibility and control.

Managing Inventory With Variations in Kechie ERP

Kechie ERP inventory management software supports variation-based inventory tracking for both stocked and manufactured items.

Key Kechie ERP Capabilities

- Define multiple variation attributes per item

- Track inventory quantities per variant

- Assign costs, pricing, and barcodes at the variation level

- Set reorder points by variant

- Maintain reporting at both parent and variant levels

This ensures inventory decisions are based on actual demand patterns, not averages.

Apparel ERP Example: Size, Color, and Gender Variations

Apparel inventory is one of the clearest examples of why variation is essential.

Base Item: Cotton T-Shirt

Variation Attributes:

- Gender (Men’s, Women’s, Unisex)

- Size (S, M, L, XL)

- Color (Black, White, Blue)

Each gender–size–color combination represents a distinct inventory unit that must be tracked independently.

An apparel ERP system like Kechie enables:

- Accurate stock tracking by size and gender

- Better demand forecasting

- Reduced returns and fulfillment errors

- Cleaner eCommerce and POS integration

Manufacturing Items With Variations in ERP Software

In manufacturing ERP systems, variations affect more than inventory—they directly impact production.

Common Manufacturing Variation Drivers

- Dimensions or sizing

- Material substitutions

- Finish or coating options

- Customer-specific configurations

How ERP Software Handles Manufacturing Variations

- Shared Bills of Materials (BOMs) with variant-specific rules

- Accurate costing per variation

- Variant-level production planning

- Material requirement planning by configuration

This is critical for furniture manufacturing, apparel production, and configurable goods.

Variation vs Separate Items in ERP Systems

A common ERP design question is whether to use variations or separate items.

Use Variations When:

- The base product is fundamentally the same

- Differences are attribute-driven

- Operational workflows overlap

Use Separate Items When:

- Function or use case differs

- Cost structure changes significantly

- Manufacturing processes diverge

ERP platforms like Kechie support both approaches, allowing businesses to model inventory realistically.

Business Benefits of Variation-Based ERP Inventory Management

Using product variations in ERP software delivers measurable benefits:

- Higher inventory accuracy

- Lower carrying costs

- Improved purchasing and production planning

- Stronger demand forecasting

- Better integration with accounting and eCommerce platforms

Variation ensures ERP systems reflect how products are actually bought, stored, and produced.

Key Takeaway

Product variation is the foundation of effective ERP inventory and manufacturing management.

Whether inventory begins without part numbers or already includes them, variation provides the structure needed for accuracy, scalability, and operational clarity. ERP software like Kechie ERP is built to manage this complexity, making variation a core component of modern inventory systems.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

Kechie Achieves Multiple 2025 Recognitions

A Mark of Excellence: Kechie Achieves Multiple 2025 Recognitions from Software Advice and GetApp

What a year! We're thrilled to announce that Kechie has received multiple accolades across Software Advice, and GetApp throughout 2025.

Kechie is an advanced cloud-based ERP solution tailored for small to midsize businesses seeking to streamline their operations across inventory, sales, procurement, and more. Our platform stands out for its flexible modular design and seamless integration capabilities, allowing organizations to scale and adapt as their needs evolve. Kechie’s innovative real-time data visibility and automated process management empower users to boost productivity and make informed decisions with confidence.

Software Advice

GetApp

Being featured in so many of their flagship reports is a powerful testament to the consistent value and quality we deliver to our users every single day.

“Kechie helped us a great deal with operations Kechie has been a life saver for us. It has real time visibility and audit traceability on everything, so we know who move what and when. Before, we’d lose items and had a hard time locating items. Kechie has also heled organize events and everything going to the events from consumables to equipment. We use the CRM to maintain our communications with our clients and any special requirements. It has been very user friendly and the team was great in training. Reporting is also very easy and helps with grant application. Overall a great system.”

[Source: Capterra]

“Kechie has made my life so much easier. I can't believe I was tracking all my inventory by hand for so long; I wish I started using this system much sooner. Cannot recommend it more. It's fast and responsive, the UI is intuitive, it's reliable.”

[Source: Capterra]

“Ease of use. ALL the reports are wonderful. Love the team, i can't thank them enough for the training.”

[Source: Capterra]

Want to review Kechie? Click here.

Looking Ahead

2025 has been remarkable, but we're just getting started. Looking ahead, we're dedicated to evolving and enhancing Kechie to meet your changing needs. We're thrilled about the opportunities on the horizon and look forward to continuing our journey of growth with you.

Executive Quote

“Our mission with Kechie has always been simple: make ERP easier to use and faster to implement without sacrificing power. These recognitions confirm what our customers already know — we’re helping operations teams finally get real-time visibility and control without the pain of traditional systems”

— Mariam Komeili, CEO, My Office Apps

About My Office Apps

My Office Apps, Inc. (MOA) is a leader in business improvement software solutions to automate your organization. In the past 11 years, MOA has offered our Kechie line of cloud-based fully integrated software solutions that serve distributors and manufacturers in many industries. Kechie is scalable with a simplified user experience and sold in separate packages – inventory and warehouse management, manufacturing, and finance – or a fully configured ERP system. One powerful cloud-based solution to connect your business processes seamlessly-Connect, Streamline, Succeed!

About Gartner Digital Markets:

Gartner Digital Markets is the world’s largest platform for finding software and services. More than 100 million people visit Capterra, GetApp, Software Advice, and UpCity across over 70 localized sites every year to read objective research and verified customer reviews that help them confidently choose the right software and services. Thousands of B2B companies work with Gartner Digital Markets to build their brand, capture buyer demand, and grow their business.

For more information, visit https://www.gartner.com/en/digital-markets

Disclaimer:

The Gartner Digital Markets badges from Capterra, GetApp, and Software Advice are trademarks and service marks of Gartner, Inc. and/or its affiliates are used herein with permission. All rights reserved. Gartner Digital Markets badges constitute the subjective opinions of individual end-user reviews, ratings, and data applied against a documented methodology; they neither represent the views of, nor constitute an endorsement by, Gartner, Inc. or its affiliates.

The Future of ERP: AI, Automation & Analytics

The Future of ERP: AI, Automation, and Analytics Powering the Next Generation of Business

The Future Is Already Here — It’s Just Unevenly Adopted

Walk into two manufacturing or distribution companies today, and you might feel like you’ve stepped into different decades.

One is buried in spreadsheets, manual reporting, and reactive decision-making. The other is running on predictive analytics, automated workflows, and real-time insights.

The difference isn’t just technology — it’s transformation.

This is the next era of Enterprise Resource Planning (ERP), where Artificial Intelligence (AI), automation, and analytics are reshaping how businesses operate.

Cloud-based systems like Kechie ERP are leading this shift, combining intelligence and integration to help growing manufacturers and distributors operate smarter, faster, and more profitably.

1. From Data Collection to Data Intelligence

Traditional ERP systems were designed to collect and store data.

But modern businesses don’t just need data — they need insight.

AI-driven ERP platforms like Kechie transform raw information into real-time intelligence.

They analyze sales trends, production metrics, and supplier performance to uncover patterns that would otherwise go unnoticed.

For example, Kechie can highlight when a particular supplier’s lead time is rising or when a product’s margins are tightening — before those issues affect your bottom line.

This is the shift from reactive to predictive — from hindsight to foresight.

2. Automation: Doing More With Less Manual Effort

Manual tasks slow teams down and invite mistakes.

Modern ERP automation takes care of those repetitive, time-consuming jobs — freeing employees to focus on strategy and service.

Kechie automates key workflows across operations:

- Reordering materials when inventory hits predefined thresholds

- Approving purchase orders or invoices based on set rules

- Generating and sending recurring reports automatically

The result? Fewer errors, faster turnaround times, and consistent accuracy across every department.

Automation doesn’t replace people — it empowers them.

3. Predictive Analytics and Smarter Decision-Making

Data becomes powerful when it helps you make the right call before problems arise.

Kechie’s built-in analytics engine uses predictive modeling to forecast demand, optimize production, and identify cost-saving opportunities.

Distributors can anticipate which SKUs are likely to run low.

Manufacturers can plan production around upcoming spikes in demand.

These insights let leaders move from reacting to issues to strategically planning around them — saving time, money, and stress.

4. AI-Powered Forecasting and Resource Planning

Artificial Intelligence is rapidly becoming the brain of ERP systems.

It doesn’t just process data — it learns from it.

Kechie uses AI algorithms to:

- Improve forecasting accuracy

- Spot inefficiencies in production or purchasing

- Recommend the optimal reorder quantities

- Suggest supplier alternatives based on performance history

With AI guiding decisions, manufacturers and distributors can better balance supply and demand, manage costs, and keep customers satisfied.

5. Connected Ecosystems and API-Driven Integrations

No business operates in isolation — and your ERP shouldn’t either.

The future of ERP lies in API-driven integration, where systems communicate fluidly and data flows seamlessly between tools.

Kechie ERP is built to connect your entire operation. It integrates smoothly with:

- Shopify for eCommerce and order management

- EDI platforms for supplier and retailer data exchange

- QuickBooks for financial synchronization

- POS systems for real-time sales visibility

- Credit card processing tools for streamlined transactions

- Shipping solutions for end-to-end fulfillment tracking

And because Kechie also includes its own CRM, you get one unified platform for customer management, sales tracking, and operational execution.

Every part of your business — from order intake to delivery — runs in perfect sync.

6. Cloud Infrastructure and Continuous Improvement

The cloud was the foundation of ERP’s evolution — but now it’s also the catalyst for ongoing innovation.

With Kechie’s cloud-native architecture, updates happen automatically, without disrupting daily work. You’re always on the latest version, always secure, and always benefiting from new capabilities.

Cloud infrastructure also supports the computing power required for AI and advanced analytics — enabling constant optimization and scalability without hardware limitations.

7. Mobile ERP and Real-Time Accessibility

In today’s distributed work environment, teams need to stay connected no matter where they are.

Kechie’s mobile-friendly design allows users to manage orders, approve transactions, and access dashboards from any device.

Warehouse managers can update inventory levels from the floor.

Sales reps can check customer histories before meetings.

Executives can track KPIs on the go.

Mobility means visibility — and visibility means control.

8. Sustainability and Smart Resource Management

Future-ready ERP systems are helping companies reduce waste, cut emissions, and optimize resource use.

With Kechie, manufacturers and distributors can:

- Track production efficiency and scrap levels

- Monitor supplier sustainability metrics

- Optimize shipping routes to lower fuel usage

By aligning operational efficiency with environmental responsibility, businesses can achieve growth that’s both profitable and sustainable.

9. The Human Side of ERP Innovation

Technology is only as valuable as the people who use it.

AI and automation aren’t replacing human intelligence — they’re amplifying it.

Kechie’s intuitive design helps every user — from warehouse teams to executives — make data-driven decisions with ease.

Instead of chasing down reports, employees can focus on improvement and innovation.

That’s the real magic of ERP evolution: people and technology working in harmony.

10. The Road Ahead: Smarter, Simpler, Seamlessly Connected

The next generation of ERP will be more intelligent, adaptive, and collaborative than ever before.

Businesses that adopt these innovations early — AI forecasting, API integrations, real-time analytics — will gain an advantage that compounds over time.

Kechie ERP embodies that future:

- Intelligent automation for speed and precision

- Real-time analytics for smarter planning

- Seamless integrations for a unified business experience

It’s not just an ERP system — it’s a growth platform designed for the modern manufacturer and distributor.

Conclusion: The Future Belongs to the Insight-Driven

The future of ERP isn’t about more technology — it’s about more clarity.

AI, automation, and connected integrations are helping businesses see further, react faster, and grow smarter.

Kechie ERP makes that future tangible — today.

By combining intelligent automation, predictive analytics, and seamless integrations, it gives you the power to make better decisions, reduce costs, and stay agile in an unpredictable world.

If you’re ready to see how technology can empower your business — not overwhelm it — the future is already waiting.

And with Kechie, it’s within reach.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!