Outgrowing QuickBooks? When a Full ERP Makes More Sense

Outgrowing QuickBooks? When a Full ERP Makes More Sense

When It’s Time to Move Beyond QuickBooks — and What a Full ERP Really Solves

QuickBooks is often the first accounting system a business adopts — and for good reason. It’s accessible, familiar, and works well in the early stages.

But for many growing companies, there comes a point where the question isn’t “How do we upgrade QuickBooks?”

It’s “Why are we still building so many workarounds around it?”

As QuickBooks Desktop continues to be phased out and more users are pushed toward QuickBooks Online, some businesses realize that simply moving accounting to the cloud doesn’t solve their bigger operational challenges. That’s usually the moment ERP enters the conversation.

What Actually Pushes Businesses Beyond QuickBooks

Most companies don’t leave QuickBooks because they dislike it.

They leave because the business outgrows what accounting software alone can support.

Common signals include:

- Inventory tracked across spreadsheets and disconnected tools

- Orders, fulfillment, and purchasing handled outside accounting

- Multiple locations or warehouses with limited visibility

- Manual reconciliation between sales, inventory, and finance

- Leadership questioning whether reports reflect reality

QuickBooks didn’t fail — it just wasn’t designed to be the operational backbone of a growing business.

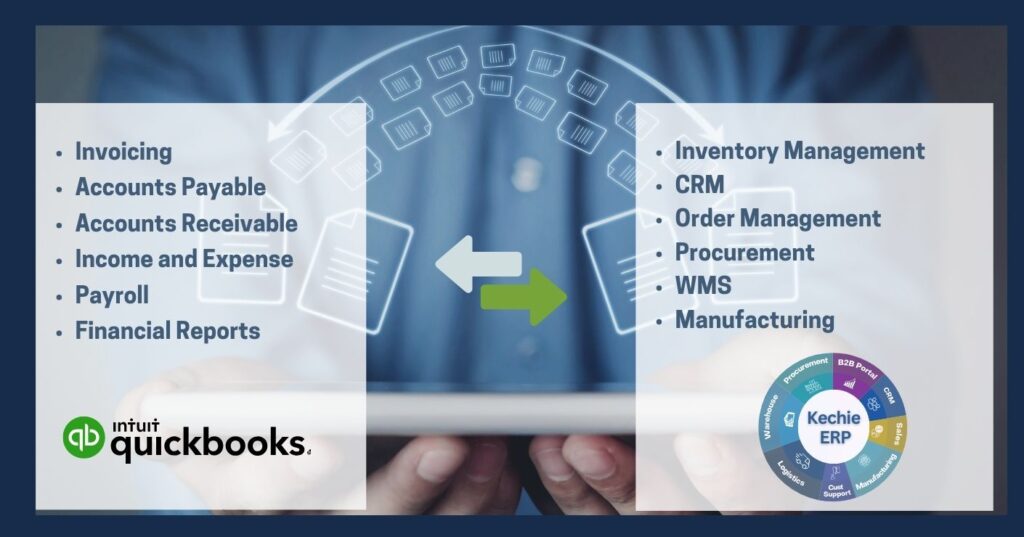

Why Moving to QBO Isn’t Always Enough

For many businesses, QuickBooks Online (QBO) is a logical next step — and for accounting-only needs, it works well.

But when inventory, operations, and reporting are central to the business, QBO often highlights the same gaps Desktop had:

- Limited inventory depth

- Minimal workflow automation

- Disconnected operational processes

At that point, businesses face a choice:

- Continue extending QuickBooks with more systems

- Or consolidate into a single platform designed to manage operations and accounting together

This is where a full ERP becomes a serious consideration.

What a Full ERP Actually Does (Without the Buzzwords)

ERP doesn’t have to be complicated.

At its core, a full ERP brings accounting, inventory, operations, and reporting into one system with a single source of truth.

Instead of syncing data between tools, teams work from real-time information across:

- Accounting and financials

- Inventory and purchasing

- Orders and fulfillment

- Customer and operational data

For growing businesses, this reduces friction, manual work, and data inconsistencies.

When a Full ERP Makes Sense

A full ERP is usually the right move when:

- Inventory accuracy directly impacts revenue or customer experience

- Operations involve multiple steps, locations, or teams

- Reporting delays slow decision-making

- Manual processes are limiting growth

- Integrations and workarounds are becoming difficult to manage

At this stage, extending QuickBooks can feel like maintaining complexity instead of reducing it.

ERP Doesn’t Have to Mean “Enterprise-Only”

One of the biggest misconceptions about ERP is that it’s only for very large companies.

Modern ERPs are built for growing, mid-market businesses that need:

- Advanced inventory and operations

- Built-in accounting

- Flexibility without enterprise bloat

- Faster implementations and lower overhead

For many companies, ERP isn’t about adding complexity — it’s about removing it.

How Businesses Typically Get Here

Most companies don’t wake up one day and decide to replace QuickBooks.

They get there gradually — after layering spreadsheets, apps, and workarounds on top of accounting software that was never meant to run the entire business.

By the time ERP enters the conversation, the real goal is usually clarity:

fewer systems, better visibility, and less manual work.

👉 Related reading:

• QuickBooks Desktop Is Being Phased Out — What Growing Businesses Should Do Next

• Why So Many Businesses Are Moving from QuickBooks Desktop to QuickBooks Online — and Where QBO Needs Help

QuickBooks Desktop to QBO: What Works — and Where QBO Falls Short

QuickBooks Desktop to QBO: What Works — and Where QBO Falls Short

Why So Many Businesses Are Moving from QuickBooks Desktop to QuickBooks Online — and Where QBO Needs Help

As QuickBooks Desktop continues to be phased out, many businesses are finding themselves pointed in one direction: QuickBooks Online (QBO).

Desktop is no longer being sold as a long-term solution, multiple Desktop versions have already been sunset, and the remaining versions are approaching end of support — including QuickBooks Desktop 2023 in May 2026. Intuit’s direction is clear: QuickBooks Online is the future.

For many businesses, QBO feels like the natural next step. But moving to QBO raises an important question:

How do you move forward without rebuilding the same workarounds you relied on with Desktop?

Why QuickBooks Online Is Often the First Step

QuickBooks Online is where Intuit is investing. It offers:

- Cloud access from anywhere

- Automatic updates and security patches

- Easier collaboration across teams

- Ongoing product support

For core accounting, QBO does exactly what it’s designed to do.

If accounting is your only challenge and inventory is minimal, QBO may be all you need.

Where QuickBooks Online Starts to Fall Short

QuickBooks Online was designed first and foremost as an accounting platform.

As businesses grow, limitations tend to show up around:

- Inventory beyond the basics

- Multiple locations or warehouses

- Order and fulfillment workflows

- Operational visibility and automation

These are often the same areas where Desktop users relied on spreadsheets, add-ons, and manual processes.

Extending QuickBooks Online Instead of Forcing It

Rather than forcing QBO to do more than it was designed for, many businesses pair it with a robust inventory and operations system.

In this setup:

- QuickBooks Online remains the system of record for accounting

- Inventory and workflows are handled outside accounting

- Data stays synced without duplicate entry

This allows teams to modernize operations without disrupting finance.

👉 Related reading:

QuickBooks Desktop Is Being Phased Out — What Growing Businesses Should Do Next

QuickBooks Desktop Is Being Phased Out: What Growing Businesses Should Do

QuickBooks Desktop Is Being Phased Out: What Growing Businesses Should Do

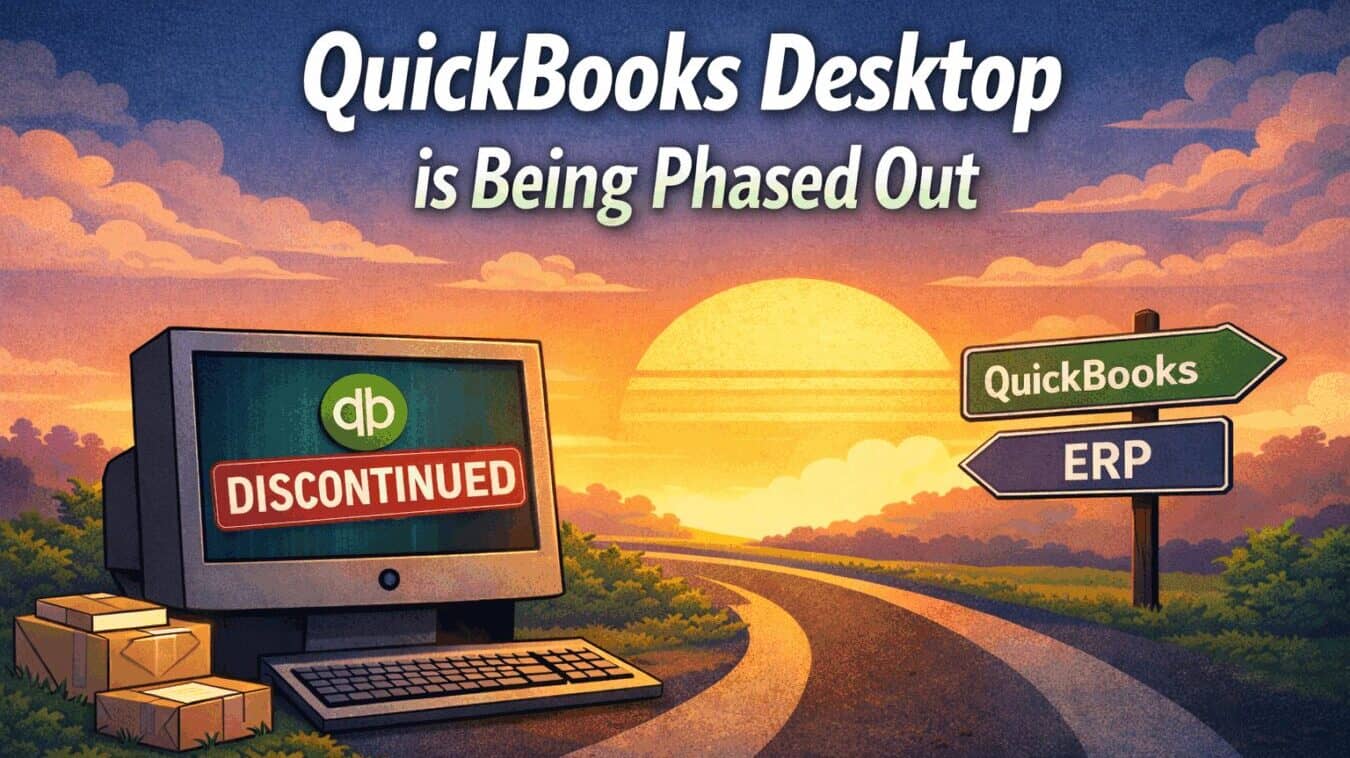

QuickBooks Desktop is being phased out — What That Really Means for Growing Businesses

If you’re a business owner, one of the first pieces of software you look for to run your business is an accounting system. And let’s face it — QuickBooks is usually the first name that comes up. It’s the biggest player in the SMB accounting market, it’s relatively simple to set up, and it’s easy for teams to learn and use.

For many companies, QuickBooks Desktop (including Enterprise) has done exactly what it was meant to do in the early stages: manage the books, keep things organized, and support day-to-day operations without much friction.

But businesses don’t stay small forever. As operations grow more complex and expectations increase, systems that once worked well can start to feel limiting. And now, with QuickBooks Desktop no longer being sold as a long-term solution, many Desktop versions have already been sunset, and Intuit’s direction is clear: all QuickBooks users are being pushed toward QuickBooks Online (QBO).

Many growing companies are reaching a natural decision point — not because QuickBooks failed them, but because they’ve outgrown what Desktop was designed to handle.

When Is QuickBooks Desktop 2023 Being Discontinued?

QuickBooks Desktop 2023 will reach end of support in May 2026. After that date, Intuit will no longer provide:

• Security updates or patches

• Technical support

• Online services like payroll, bank feeds, and integrations

While the software may still open, it will be unsupported. For businesses that rely on accurate financials, inventory visibility, or compliance, running core operations on unsupported software introduces real risk over time.

Can You Keep Using QuickBooks Desktop After May 2026?

Technically, yes — but practically, it becomes risky very quickly.

Once support ends, even small issues can snowball. Integrations stop syncing, updates no longer install cleanly, and manual workarounds start creeping in. Most companies don’t realize how dependent they are on Desktop until it begins slowing everything else down.

For growing teams, unsupported software often becomes a hidden bottleneck.

Why This Impacts QuickBooks Enterprise Users More Than Others

Enterprise users typically rely on QuickBooks for much more than basic bookkeeping.

Many are managing:

• Multiple warehouses or locations

• Inventory that needs to be accurate, not “close enough”

• High transaction volumes

• Reporting leadership depends on

To keep Desktop working, teams often layer on spreadsheets, add-ons, and manual processes. It works — until it doesn’t.

The sunset forces an honest question:

Are you running your business, or are you working around your system?

What Are Growing Businesses Doing Instead?

As May 2026 approaches, most QuickBooks Enterprise users find themselves evaluating one of two realistic paths.

Path 1: Move to QuickBooks Online — and Decide How Much More You Actually Need

For businesses that want to stay in the QuickBooks ecosystem, QuickBooks Online (QBO) is often the next step. It offers cloud access, automatic updates, and continued support.

If accounting is your only real challenge, and you don’t rely heavily on inventory, orders, or operational workflows, then moving to QBO may be all you need.

For growing businesses, however, accounting is usually just one piece of the puzzle. As inventory, fulfillment, and operations become more complex, many teams realize that QBO alone doesn’t replace the workarounds they relied on in Desktop.

That’s why many businesses choose to move to QuickBooks Online with a robust inventory and operations platform — keeping QuickBooks for accounting, while managing inventory, orders, and workflows in a system built for scale.

👉 Related reading:

Why So Many Businesses Are Moving from QuickBooks Desktop to QuickBooks Online — and Where QBO Needs Help

Path 2: Move Beyond QuickBooks Entirely

For other businesses, the sunset is an opportunity to simplify.

Instead of managing accounting, inventory, CRM, and reporting across multiple systems, they move to a single cloud platform that brings everything together — including accounting.

👉 Related reading:

When It’s Time to Replace QuickBooks with a Full Cloud ERP

In This Article

-When Is QuickBooks Desktop 2023 Being Discontinued?

-Can You Keep Using QuickBooks Desktop After May 2026?

-Why This Impacts QuickBooks Enterprise Users More Than Others

-What Are Growing Businesses Doing Instead?

-Path 1: Move to QuickBooks Online

-Path 2: Move Beyond QuickBooks Entirely

Top 12 Cloud-Based ERP Systems for Distribution

Top 12 Cloud-Based ERP Systems for Distribution

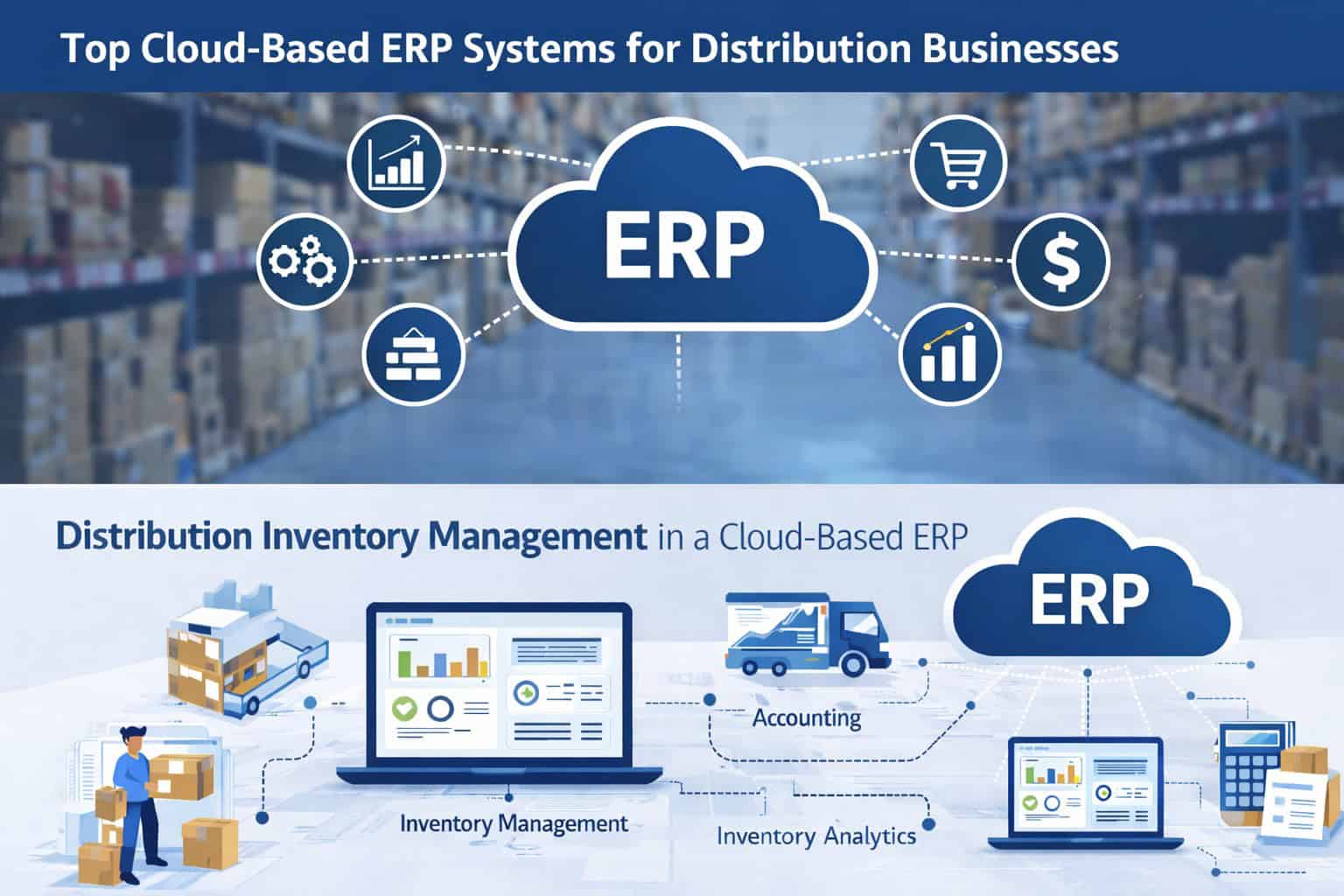

Distribution and inventory-heavy businesses operate in one of the most operationally demanding environments today. Managing thousands of SKUs, multiple warehouses, purchasing cycles, fulfillment, and real-time financials requires far more than disconnected accounting and inventory tools.

A modern cloud-based ERP software platform centralizes inventory, purchasing, sales, fulfillment, and accounting into a single system—providing the visibility and control distributors need to scale efficiently.

This guide breaks down the top 12 cloud-based ERP systems specifically suited for distribution, wholesale, and inventory-driven businesses, with a focus on inventory depth, operational efficiency, and long-term scalability.

Why Distribution Businesses Need a Cloud-Based ERP

Distribution companies face unique challenges, including:

- High-volume inventory management

- FIFO and lot-tracked inventory

- Multi-warehouse visibility

- Complex purchasing and vendor relationships

- Tight coordination between inventory, sales, and accounting

Compared to legacy systems, a cloud ERP vs on-premise ERP solution offers real-time access, lower infrastructure costs, automatic updates, and faster scalability—key advantages for growing distributors.

Quick Comparison: Best Cloud ERP for Distribution

Top 12 Cloud-Based ERP Systems for Distribution

1. NetSuite ERP (Oracle NetSuite)

Best for: Large-scale distribution operations

Strengths for distribution:

- Multi-warehouse inventory management

- Advanced demand planning and procurement

- Strong financial controls and compliance

Best fit & things to know:

Well suited for larger distribution organizations with complex structures and the resources to support a more involved implementation.

2. SAP S/4HANA Cloud

Best for: Enterprise distribution networks

Strengths for distribution:

- End-to-end supply chain visibility

- High-volume transaction processing

- Advanced analytics and forecasting

Best fit & things to know:

Designed primarily for enterprise-scale operations and global supply chains.

3. Microsoft Dynamics 365 Business Central

Best for: Growing SMB distributors

Strengths for distribution:

- Inventory and warehouse management

- Tight integration with Excel, Power BI, and Outlook

- Flexible ecosystem of industry extensions

Best fit & things to know:

A strong choice for SMB distributors, with additional extensions available for more complex workflows.

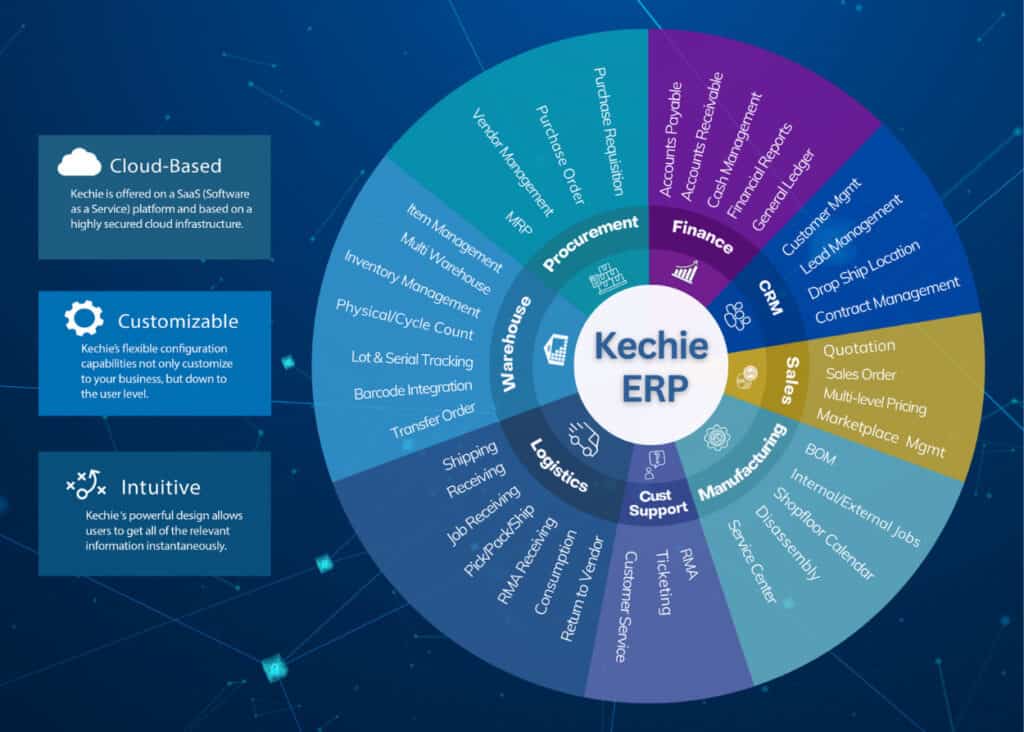

4. Kechie ERP

Best for: Inventory-heavy distributors seeking flexibility

Kechie is a cloud-based ERP built specifically for inventory-driven businesses and is designed for distributors and wholesalers that have outgrown basic accounting software.

Strengths for distribution:

- Advanced inventory control including FIFO, lot tracking, and serialization

- Purchasing, sales orders, fulfillment, and accounting in one system

- Built-in CRM fully connected to inventory and financials

- Real-time dashboards for inventory levels and margins

Best fit & things to know:

Ideal for growing distribution and wholesale businesses that need strong inventory control without enterprise-level complexity.

5. Acumatica Cloud ERP

Best for: Distribution businesses seeking scalable pricing

Strengths for distribution:

- Robust inventory and order management

- Flexible warehouse and logistics capabilities

- Resource-based pricing model

Best fit & things to know:

Popular among distributors looking for scalability without per-user licensing constraints.

6. Infor CloudSuite Distribution

Best for: Industry-specific distribution workflows

Strengths for distribution:

- Industry-focused process design

- AI-driven demand insights

- Strong supply chain planning tools

Best fit & things to know:

A good option for distributors seeking industry-specific ERP workflows.

7. Epicor Kinetic (Cloud)

Best for: Distributors with light manufacturing or kitting

Strengths for distribution:

- Inventory and production alignment

- Strong demand planning and scheduling

- Cloud and hybrid deployment options

Best fit & things to know:

Well suited for businesses combining distribution with light manufacturing or assembly.

8. Odoo Enterprise

Best for: Modular ERP adoption

Strengths for distribution:

- Inventory, purchasing, and sales modules

- Cost-effective and modular design

- Open-source flexibility

Best fit & things to know:

Attractive for distributors that want modular control and have technical resources available.

9. Syspro Cloud ERP

Best for: Mid-sized distributors

Strengths for distribution:

- Strong inventory costing and traceability

- Warehouse management tools

- Distribution-focused reporting

Best fit & things to know:

A solid option for mid-sized distribution businesses prioritizing inventory accuracy.

10. Priority ERP

Best for: International distribution businesses

Strengths for distribution:

- Multi-entity and multi-currency support

- Customizable workflows

- Global compliance capabilities

Best fit & things to know:

Often selected by distributors operating across multiple regions.

11. Zoho Inventory + Finance Stack

Best for: Small distributors with simpler operations

Strengths for distribution:

- Affordable and easy to use

- Integrated sales and inventory tools

Best fit & things to know:

Works well for smaller teams and less complex inventory environments.

12. Workday Financial Management

Best for: Financial-centric enterprises

Strengths:

- Advanced financial planning and analytics

Best fit & things to know:

Primarily focused on finance and HR rather than inventory-heavy distribution operations.

How to Choose the Right Cloud ERP for Distribution

When evaluating ERP systems for distribution businesses, prioritize:

- Real-time inventory visibility

- Multi-warehouse management

- Tight integration between inventory, purchasing, sales, and accounting

- Scalability without heavy customization

Many wholesale and distribution companies find that mid-market ERPs offer the best balance between functionality and cost.

Cloud ERP Trends for Inventory-Heavy Businesses in 2026

- AI-driven demand forecasting

- ERP and CRM convergence

- Configuration over customization

- Real-time inventory and margin analytics

Final Thoughts

The best cloud-based ERP for distribution is not the most complex system—it’s the one that provides clarity, control, and scalability without slowing operations down.

As inventory volumes grow and customer expectations rise, investing in the right ERP for inventory management becomes a competitive advantage and a foundation for long-term growth.

Frequently Asked Questions

What is the best cloud-based ERP for distribution businesses?

The best cloud-based ERP for distribution depends on inventory complexity, warehouse count, and growth plans. Platforms like Kechie, Acumatica, and Business Central are popular among inventory-heavy distributors due to their balance of functionality and usability.

Is cloud ERP suitable for inventory-heavy operations?

Yes. Modern cloud ERP systems are designed to support FIFO inventory, lot tracking, serialization, and multi-warehouse management, making them ideal for distribution and wholesale businesses.

How much does a cloud-based ERP system cost?

Cloud ERP pricing varies based on features, users, and business size. SMB-focused platforms typically offer more predictable pricing than enterprise solutions.

What are the benefits of cloud ERP over on-premise ERP?

Cloud ERP offers real-time access, lower infrastructure costs, automatic updates, and faster scalability compared to on-premise systems.

What Is Product Variation?

What Is Product Variation?

Product variation refers to managing multiple versions of the same base product using defined attributes rather than creating separate, disconnected items.

Each unique combination of attributes creates a variant, which can be tracked independently for inventory, purchasing, manufacturing, and fulfillment.

Common Product Variation Attributes

| Size | Finish |

| Color | Configuration |

| Gender | Length, weight, or capacity |

| Material | Packaging or bundle type |

Variation allows businesses to offer flexibility to customers while maintaining operational control in ERP systems.

Why Product Variation Is Essential in ERP Inventory Management

Variation exists because real-world inventory decisions happen at the variant level, not the product level.

Without proper variation modeling, businesses experience:

- Stockouts in specific sizes or colors

- Over-purchasing of slow-moving variants

- Inaccurate inventory valuation

- Fulfillment and picking errors

- Weak demand forecasting

ERP inventory management systems rely on variation to ensure accuracy, traceability, and scalability.

Managing Inventory Without Part Numbers Using Variations

Many businesses begin operations without standardized part numbers or SKUs. This is common in:

- Apparel and fashion

- Furniture and home goods

- Custom manufacturing

- Contract production

- Early-stage or fast-growing companies

Parent Item + Variation Model

ERP systems like Kechie address this using a parent item with variation attributes.

How This Works in Practice

- A base (parent) item represents the generic product

- Variation attributes define differences (size, color, gender, etc.)

- Inventory is tracked at the variant level

- Formal SKUs or part numbers can be introduced later

This approach allows businesses to operate immediately while maintaining inventory visibility and control.

Managing Inventory With Variations in Kechie ERP

Kechie ERP inventory management software supports variation-based inventory tracking for both stocked and manufactured items.

Key Kechie ERP Capabilities

- Define multiple variation attributes per item

- Track inventory quantities per variant

- Assign costs, pricing, and barcodes at the variation level

- Set reorder points by variant

- Maintain reporting at both parent and variant levels

This ensures inventory decisions are based on actual demand patterns, not averages.

Apparel ERP Example: Size, Color, and Gender Variations

Apparel inventory is one of the clearest examples of why variation is essential.

Base Item: Cotton T-Shirt

Variation Attributes:

- Gender (Men’s, Women’s, Unisex)

- Size (S, M, L, XL)

- Color (Black, White, Blue)

Each gender–size–color combination represents a distinct inventory unit that must be tracked independently.

An apparel ERP system like Kechie enables:

- Accurate stock tracking by size and gender

- Better demand forecasting

- Reduced returns and fulfillment errors

- Cleaner eCommerce and POS integration

Manufacturing Items With Variations in ERP Software

In manufacturing ERP systems, variations affect more than inventory—they directly impact production.

Common Manufacturing Variation Drivers

- Dimensions or sizing

- Material substitutions

- Finish or coating options

- Customer-specific configurations

How ERP Software Handles Manufacturing Variations

- Shared Bills of Materials (BOMs) with variant-specific rules

- Accurate costing per variation

- Variant-level production planning

- Material requirement planning by configuration

This is critical for furniture manufacturing, apparel production, and configurable goods.

Variation vs Separate Items in ERP Systems

A common ERP design question is whether to use variations or separate items.

Use Variations When:

- The base product is fundamentally the same

- Differences are attribute-driven

- Operational workflows overlap

Use Separate Items When:

- Function or use case differs

- Cost structure changes significantly

- Manufacturing processes diverge

ERP platforms like Kechie support both approaches, allowing businesses to model inventory realistically.

Business Benefits of Variation-Based ERP Inventory Management

Using product variations in ERP software delivers measurable benefits:

- Higher inventory accuracy

- Lower carrying costs

- Improved purchasing and production planning

- Stronger demand forecasting

- Better integration with accounting and eCommerce platforms

Variation ensures ERP systems reflect how products are actually bought, stored, and produced.

Key Takeaway

Product variation is the foundation of effective ERP inventory and manufacturing management.

Whether inventory begins without part numbers or already includes them, variation provides the structure needed for accuracy, scalability, and operational clarity. ERP software like Kechie ERP is built to manage this complexity, making variation a core component of modern inventory systems.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

The Future of ERP: AI, Automation & Analytics

The Future of ERP: AI, Automation, and Analytics Powering the Next Generation of Business

The Future Is Already Here — It’s Just Unevenly Adopted

Walk into two manufacturing or distribution companies today, and you might feel like you’ve stepped into different decades.

One is buried in spreadsheets, manual reporting, and reactive decision-making. The other is running on predictive analytics, automated workflows, and real-time insights.

The difference isn’t just technology — it’s transformation.

This is the next era of Enterprise Resource Planning (ERP), where Artificial Intelligence (AI), automation, and analytics are reshaping how businesses operate.

Cloud-based systems like Kechie ERP are leading this shift, combining intelligence and integration to help growing manufacturers and distributors operate smarter, faster, and more profitably.

1. From Data Collection to Data Intelligence

Traditional ERP systems were designed to collect and store data.

But modern businesses don’t just need data — they need insight.

AI-driven ERP platforms like Kechie transform raw information into real-time intelligence.

They analyze sales trends, production metrics, and supplier performance to uncover patterns that would otherwise go unnoticed.

For example, Kechie can highlight when a particular supplier’s lead time is rising or when a product’s margins are tightening — before those issues affect your bottom line.

This is the shift from reactive to predictive — from hindsight to foresight.

2. Automation: Doing More With Less Manual Effort

Manual tasks slow teams down and invite mistakes.

Modern ERP automation takes care of those repetitive, time-consuming jobs — freeing employees to focus on strategy and service.

Kechie automates key workflows across operations:

- Reordering materials when inventory hits predefined thresholds

- Approving purchase orders or invoices based on set rules

- Generating and sending recurring reports automatically

The result? Fewer errors, faster turnaround times, and consistent accuracy across every department.

Automation doesn’t replace people — it empowers them.

3. Predictive Analytics and Smarter Decision-Making

Data becomes powerful when it helps you make the right call before problems arise.

Kechie’s built-in analytics engine uses predictive modeling to forecast demand, optimize production, and identify cost-saving opportunities.

Distributors can anticipate which SKUs are likely to run low.

Manufacturers can plan production around upcoming spikes in demand.

These insights let leaders move from reacting to issues to strategically planning around them — saving time, money, and stress.

4. AI-Powered Forecasting and Resource Planning

Artificial Intelligence is rapidly becoming the brain of ERP systems.

It doesn’t just process data — it learns from it.

Kechie uses AI algorithms to:

- Improve forecasting accuracy

- Spot inefficiencies in production or purchasing

- Recommend the optimal reorder quantities

- Suggest supplier alternatives based on performance history

With AI guiding decisions, manufacturers and distributors can better balance supply and demand, manage costs, and keep customers satisfied.

5. Connected Ecosystems and API-Driven Integrations

No business operates in isolation — and your ERP shouldn’t either.

The future of ERP lies in API-driven integration, where systems communicate fluidly and data flows seamlessly between tools.

Kechie ERP is built to connect your entire operation. It integrates smoothly with:

- Shopify for eCommerce and order management

- EDI platforms for supplier and retailer data exchange

- QuickBooks for financial synchronization

- POS systems for real-time sales visibility

- Credit card processing tools for streamlined transactions

- Shipping solutions for end-to-end fulfillment tracking

And because Kechie also includes its own CRM, you get one unified platform for customer management, sales tracking, and operational execution.

Every part of your business — from order intake to delivery — runs in perfect sync.

6. Cloud Infrastructure and Continuous Improvement

The cloud was the foundation of ERP’s evolution — but now it’s also the catalyst for ongoing innovation.

With Kechie’s cloud-native architecture, updates happen automatically, without disrupting daily work. You’re always on the latest version, always secure, and always benefiting from new capabilities.

Cloud infrastructure also supports the computing power required for AI and advanced analytics — enabling constant optimization and scalability without hardware limitations.

7. Mobile ERP and Real-Time Accessibility

In today’s distributed work environment, teams need to stay connected no matter where they are.

Kechie’s mobile-friendly design allows users to manage orders, approve transactions, and access dashboards from any device.

Warehouse managers can update inventory levels from the floor.

Sales reps can check customer histories before meetings.

Executives can track KPIs on the go.

Mobility means visibility — and visibility means control.

8. Sustainability and Smart Resource Management

Future-ready ERP systems are helping companies reduce waste, cut emissions, and optimize resource use.

With Kechie, manufacturers and distributors can:

- Track production efficiency and scrap levels

- Monitor supplier sustainability metrics

- Optimize shipping routes to lower fuel usage

By aligning operational efficiency with environmental responsibility, businesses can achieve growth that’s both profitable and sustainable.

9. The Human Side of ERP Innovation

Technology is only as valuable as the people who use it.

AI and automation aren’t replacing human intelligence — they’re amplifying it.

Kechie’s intuitive design helps every user — from warehouse teams to executives — make data-driven decisions with ease.

Instead of chasing down reports, employees can focus on improvement and innovation.

That’s the real magic of ERP evolution: people and technology working in harmony.

10. The Road Ahead: Smarter, Simpler, Seamlessly Connected

The next generation of ERP will be more intelligent, adaptive, and collaborative than ever before.

Businesses that adopt these innovations early — AI forecasting, API integrations, real-time analytics — will gain an advantage that compounds over time.

Kechie ERP embodies that future:

- Intelligent automation for speed and precision

- Real-time analytics for smarter planning

- Seamless integrations for a unified business experience

It’s not just an ERP system — it’s a growth platform designed for the modern manufacturer and distributor.

Conclusion: The Future Belongs to the Insight-Driven

The future of ERP isn’t about more technology — it’s about more clarity.

AI, automation, and connected integrations are helping businesses see further, react faster, and grow smarter.

Kechie ERP makes that future tangible — today.

By combining intelligent automation, predictive analytics, and seamless integrations, it gives you the power to make better decisions, reduce costs, and stay agile in an unpredictable world.

If you’re ready to see how technology can empower your business — not overwhelm it — the future is already waiting.

And with Kechie, it’s within reach.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

How to Migrate from On-Premise ERP to Cloud

How to Migrate from On-Premise ERP to the Cloud — A Step-by-Step Guide

You Know It’s Time for a Change — Here’s How to Make It Smooth

In our last article, we explored the advantages of cloud ERP systems and how they help growing manufacturers and distributors stay competitive.

Now, let’s tackle the question that comes next for many business owners:

“How do we actually move from our old, on-premise ERP to the cloud?”

For most companies, the move to cloud ERP feels both exciting and intimidating. The promise of better visibility and automation is huge — but so are the concerns about data migration, downtime, and team adoption.

The good news? With the right plan, partner, and preparation, the transition can be smooth, efficient, and even energizing for your entire organization.

Here’s a practical step-by-step guide to help you migrate confidently — and how solutions like Kechie make it easier.

Step 1: Evaluate Your Current ERP System

Before making any move, take an honest look at where you stand.

What’s working in your current ERP — and what’s not?

Ask questions like:

- Are there data silos between departments?

- Is it difficult to access reports or analytics?

- Does the system require manual updates or IT support?

- Are maintenance costs rising each year?

This evaluation will help you pinpoint the gaps that cloud ERP can fill. Many manufacturers and distributors realize that their old systems simply can’t keep up with their growth. Kechie’s team often begins engagements with a thorough discovery process to uncover these inefficiencies before migration even begins.

Step 2: Define Clear Goals and Success Metrics

Migration isn’t just about moving data — it’s about improving how you work.

Start by setting measurable goals:

- Faster order processing times

- Reduced inventory discrepancies

- Better access to real-time financial data

- Lower operational costs

With Kechie, goal setting is built into the implementation plan. Their experts help align your ERP configuration with your unique business processes — ensuring you’re not just transferring information but transforming how your teams operate.

Step 3: Choose the Right Cloud ERP Partner

The partner you choose determines how easy (or painful) your migration will be.

Look for a solution that offers:

- Industry expertise in manufacturing and distribution

- Proven migration tools and data mapping capabilities

- Secure, cloud-native architecture

- Responsive support and onboarding assistance

Kechie was built specifically for these industries, so it understands the complexity of multi-warehouse operations, FIFO tracking, and inventory management. More importantly, Kechie’s migration process is guided — meaning you have a clear roadmap, from setup to go-live.

Step 4: Prepare and Cleanse Your Data

This is the step where many migrations succeed or fail.

Your new ERP system is only as good as the data you bring into it.

Take the time to:

- Eliminate duplicate or outdated records

- Standardize naming conventions and units of measure

- Validate key fields (SKUs, supplier IDs, customer codes)

- Back up all existing data

Kechie’s implementation team uses automated tools to help clean and structure data before import — ensuring that once your cloud system is live, everything is consistent, accurate, and ready to go.

Step 5: Plan Your Implementation Timeline

Every company’s migration timeline looks different. Some opt for a phased rollout, starting with finance and inventory before expanding into CRM or production. Others prefer a big-bang approach — migrating everything at once for a faster transition.

Cloud ERP makes both possible. Because it’s hosted online, there’s no need for complex server setup or software installation.

Kechie supports both phased and full implementations, helping you pick the best fit for your resources, data complexity, and comfort level.

Step 6: Test Thoroughly Before You Go Live

Testing is where you build confidence.

Create a sandbox or test environment that mirrors your live setup. Have users from each department walk through their day-to-day tasks — entering orders, running reports, adjusting inventory.

This “dress rehearsal” will surface small issues early, allowing you to fine-tune workflows and permissions.

With Kechie, testing and validation are built into the onboarding process, ensuring your system is stable before flipping the switch.

Step 7: Train Your Team Early and Often

Even the best software fails if users aren’t comfortable with it.

That’s why training is one of the most critical (and often underestimated) steps in any ERP migration.

Kechie’s interface is designed for simplicity, but effective adoption still requires guidance.

Offer hands-on sessions by role — finance, operations, warehouse, etc. — and create “super users” within each team who can act as internal champions.

When people see how much time the system saves them, they embrace it quickly.

Step 8: Go Live With Confidence

Once testing and training are complete, it’s time to go live.

On launch day:

- Ensure all integrations are working (accounting, CRM, eCommerce).

- Monitor transactions closely for accuracy.

- Keep your old system available temporarily, just in case.

With cloud ERP, there’s no lengthy downtime or hardware transition. You simply log in to your new system — and start working smarter. Kechie’s implementation specialists typically stay closely involved during the first few weeks after go-live to handle questions, adjustments, or unexpected issues.

Step 9: Monitor, Measure, and Optimize

Migration doesn’t end at go-live. It’s an ongoing process of improvement.

Once your system is running, track key performance indicators (KPIs) such as:

- Order-to-cash cycle time

- Inventory turnover rate

- Forecast accuracy

- Customer satisfaction

These metrics show the tangible ROI of your ERP investment.

Kechie’s built-in analytics dashboards make it easy to visualize these metrics and identify opportunities for further automation or efficiency gains.

Step 10: Avoid Common Migration Pitfalls

Here are some common mistakes companies make — and how to avoid them:

- Rushing data migration without cleaning your records

- Skipping user testing, which can lead to confusion post-launch

- Ignoring change management, causing low adoption rates

- Not allocating enough resources for ongoing optimization

Remember: a well-planned migration is not just an IT project — it’s an operational transformation. Take your time to get it right.

Why Moving to Kechie Makes Migration Easier

Migrating to the cloud doesn’t have to be painful — especially with a system designed to make it simple.

Kechie is 100% cloud-native, so there’s no hardware setup or version management. Its modular design means you can migrate in phases, starting with the areas that bring the fastest ROI.

And with hands-on support from experienced ERP specialists, you’ll have guidance at every step.

Many manufacturers and distributors report that after migrating to Kechie, they not only streamlined their operations but also uncovered insights they’d never had before — turning what used to be chaos into clarity.

Conclusion: A Smarter Way to Modernize

Migrating from an on-premise ERP to the cloud may sound daunting, but in reality, it’s one of the smartest moves a growing business can make.

It’s not just about upgrading your software — it’s about unlocking speed, scalability, and data-driven decision-making.

With the right strategy, partner, and preparation, your ERP migration can be smooth, predictable, and transformative.

Kechie ERP helps make that possible — guiding you from planning to go-live and beyond with a platform built to support real growth.

If you’re ready to leave legacy systems behind and embrace the future, now’s the time to start your cloud ERP journey — one smart step at a time.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

10 Advantages of Cloud ERP for Growing Manufacturers and Distributors

10 Advantages of Cloud ERP for Growing Manufacturers and Distributors

If You Think ERP Is Just About Data, Think Again

In our last article, we explored what a cloud-based ERP is and how it works.

Now, let’s talk about why it matters — especially for manufacturers and distributors who are growing fast and trying to stay ahead of complexity.

For many businesses, success brings new challenges: too many spreadsheets, disconnected systems, and limited visibility. Operations start to feel like a game of catch-up. That’s when modern, cloud-based ERP solutions like Kechie become a game-changer.

Below are ten real-world advantages that explain why cloud ERP isn’t just a technology upgrade — it’s a growth strategy.

1. Real-Time Visibility Across Your Entire Business

When your systems talk to each other, everything changes.

A cloud ERP like Kechie gives you one source of truth for your data — from production to finance to inventory.

Instead of waiting for weekly reports, you can see what’s happening right now. Inventory levels, order status, production bottlenecks, and customer trends update in real time.

For high-growth companies, this visibility helps leaders spot inefficiencies, pivot quickly, and make smarter, faster decisions.

2. Flexibility That Grows With You

Growth is exciting — until your systems can’t keep up.

Cloud ERP scales effortlessly. Need to add a new warehouse, product line, or user group? It takes minutes, not months.

With Kechie, manufacturers and distributors can expand without worrying about installing new servers or disrupting operations. You start with the modules you need and add more as you grow — finance, inventory, CRM, purchasing, or production.

That flexibility keeps your business nimble, even as complexity increases.

3. Lower Total Cost of Ownership

Traditional ERP systems often require big upfront costs: servers, hardware, dedicated IT staff, and long implementation cycles.

Cloud ERP flips that model. With Kechie, there’s no heavy infrastructure to maintain. The system is web-based and subscription-driven, so you only pay for what you use.

Updates, backups, and security are handled automatically — freeing your team to focus on running the business, not running the software.

4. Faster Implementation and Easier Upgrades

On-premise ERP implementations can take months — sometimes even a year. Cloud ERP solutions are far quicker to deploy because there’s no hardware setup or manual configuration.

Kechie’s cloud deployment model means you can be up and running in a fraction of the time.

And when it’s time for upgrades, they happen behind the scenes. No downtime. No disruptions. Just the newest features, automatically applied.

5. Enhanced Collaboration Across Teams

For many companies, data lives in silos — accounting has one version, operations another, sales a third. That disconnect leads to delays, errors, and frustration.

Cloud ERP solves this by connecting everyone on the same platform.

Your sales team can check inventory before quoting a customer. Your production team can see new orders instantly. Finance can reconcile transactions in real time.

Kechie takes this a step further with role-based dashboards, so each department sees what matters most to them — without being overwhelmed by irrelevant data.

6. Improved Inventory Control and Supply Chain Management

Inventory is often where profits leak unnoticed — too much stock, slow turnover, or misplaced items.

Cloud ERP systems like Kechie give you complete visibility and control. You can track inventory across multiple warehouses, automate reordering, and even use FIFO (First-In, First-Out) tracking for perishable or high-turnover items.

For distributors, that means fewer stockouts and happier customers. For manufacturers, it means smarter production planning and lower carrying costs.

7. Seamless Integration With Other Business Tools

Modern businesses rely on multiple platforms — accounting software, eCommerce, CRMs, logistics systems. The problem is, those tools rarely talk to each other.

Kechie is built to integrate seamlessly with platforms like QuickBooks Online, Shopify, and other cloud applications.

That means no double data entry, fewer errors, and a single connected workflow from order to fulfillment.

8. Security and Data Protection You Can Trust

Some businesses hesitate to move to the cloud because they worry about security. The reality?

Top-tier cloud ERP systems are often more secure than on-premise ones.

Kechie uses enterprise-grade encryption, regular security audits, and redundant data backups in secure data centers.

Unlike a local server, which can fail or be breached, cloud environments are monitored continuously and updated automatically.

In today’s world of cyber threats and data regulations, that peace of mind is invaluable.

9. Continuous Innovation and Future-Ready Features

The beauty of cloud software is that it never stops evolving.

Kechie continuously updates its platform, rolling out new features that leverage AI, automation, and analytics — without requiring any manual installations or upgrades from your side.

That means your ERP grows smarter over time.

As manufacturing and distribution trends shift — from IoT connectivity to predictive analytics — your business stays ahead, not behind.

10. Better Decision-Making Through Real-Time Insights

At the end of the day, cloud ERP is about making better decisions faster.

Instead of relying on static reports, you get live dashboards that show what’s really happening across your business.

Kechie’s analytics tools let you track KPIs like inventory turnover, order fulfillment rates, and gross margin — all in real time.

That level of insight empowers leaders to act proactively, not reactively. You can identify inefficiencies, fine-tune operations, and seize opportunities before competitors do.

The Ripple Effect: How These Advantages Multiply

Each of these ten advantages is powerful on its own — but together, they transform how your business operates.

- Real-time data fuels faster, more confident decisions.

- Automation reduces manual work and human error.

- Integration breaks down silos between teams.

- Scalability ensures you’re never stuck with yesterday’s system.

In other words, cloud ERP gives growing companies the kind of agility that used to be reserved for enterprise giants.

When your systems are connected, your team aligned, and your data reliable, growth stops feeling chaotic — and starts feeling controlled.

Why Kechie Stands Out

Plenty of ERP solutions promise cloud flexibility. Few are built from the ground up with distributors and manufacturers in mind.

Kechie ERP is designed specifically for the challenges you face every day:

- Managing inventory across multiple warehouses

- Handling high order volumes

- Coordinating production and purchasing efficiently

- Keeping costs down while scaling up

Its modular design means you can start small — and grow without ever outgrowing your system.

And because it’s truly cloud-native, Kechie delivers updates, integrations, and innovations continuously — ensuring your business is always equipped with the best tools available.

The Bottom Line

For fast-growing manufacturers and distributors, cloud ERP isn’t just a nice-to-have — it’s the foundation of sustainable growth.

It connects every corner of your operation, cuts down on wasted time and resources, and gives you the data clarity you need to make confident moves.

Kechie brings all these advantages together in one flexible, scalable, and secure platform built for the realities of modern business.

If you’re ready to move beyond spreadsheets and fragmented systems, now’s the time to explore how cloud ERP can help you operate smarter, faster, and stronger.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

Cloud-Based ERP Explained: How Kechie Empowers Manufacturers & Distributors

What Is a Cloud-Based ERP and How Does It Work? A Modern Guide for Growing Manufacturers and Distributors

The Manufacturing World Has Changed — Has Your Software?

Walk into almost any warehouse or production floor today, and you’ll hear the same story:

Operations are busier than ever, customer expectations are higher than ever, and spreadsheets just can’t keep up.

For growing manufacturers and distributors, the real bottleneck isn’t in the warehouse — it’s in the software.

That’s why so many are making the move to cloud-based ERP systems like Kechie.

Cloud ERP isn’t just another tech buzzword. It’s a complete shift in how businesses run their day-to-day operations, manage data, and make decisions. It’s what happens when modern software finally catches up with how fast you need to move.

So, What Exactly Is a Cloud-Based ERP?

Let’s start simple.

ERP, or Enterprise Resource Planning, is the software that keeps your entire business connected — finance, inventory, purchasing, sales, production, customer management, and more.

A cloud-based ERP does everything a traditional ERP does, except it runs in the cloud — meaning it’s hosted online instead of on servers in your office.

That one difference changes everything.

No bulky hardware. No constant IT maintenance. No waiting for software updates or worrying about backups.

You log in from anywhere — whether you’re in the office, on the road, or walking the floor — and you’re in.

Cloud ERP systems like Kechie bring all your critical business data into one centralized platform, updated in real time. Every department sees the same truth — no version conflicts, no duplicate entries, and no surprises.

Why Manufacturers and Distributors Are Moving to the Cloud

The manufacturing and distribution sectors have always run on precision. But growth introduces complexity — more warehouses, more SKUs, more suppliers, more moving parts.

Traditional systems, especially on-premise ones, just can’t keep up with that pace.

Here are the biggest reasons why companies are making the switch:

1.Visibility You Can Actually Use

Imagine knowing your exact inventory levels, order status, and cash flow at any given moment — across every warehouse or location.

That’s the power of cloud ERP.

With real-time dashboards and reports, you don’t have to wait until the end of the week or month to see what’s really happening.

Kechie, for example, lets you track production runs, shipments, and financial metrics from one interface. You can spot bottlenecks before they turn into problems and make faster, smarter decisions.

2. It Grows When You Do

Growth should be exciting — not a logistical nightmare.

Cloud ERP scales naturally. Need to add a new warehouse? Hire a new sales team? Launch a new product line? You can expand your ERP with a few clicks instead of a full IT project.

That flexibility is crucial for distributors and manufacturers who often need to pivot quickly to meet customer demand or supply chain changes.

3. Fewer IT Headaches (and Costs)

Maintaining on-premise servers and outdated software is expensive — not just in dollars, but in time. Cloud ERP eliminates that overhead. Updates, backups, and security are handled by the provider.

Your team can focus on what they do best: building products, fulfilling orders, and growing the business.

4. A System That Moves as Fast as You Do

Because cloud ERP systems are web-based, your team can access information anytime, anywhere — whether they’re at a supplier site, customer meeting, or trade show.

Remote collaboration becomes seamless. Your sales, warehouse, and finance teams can finally stay in sync without endless email chains or spreadsheets.

How Does Cloud ERP Actually Work?

At a high level, a cloud-based ERP connects every part of your business through one central database hosted online.

Each department — from purchasing to accounting to operations — works from that same live data set.

Here’s a simplified view of how it all ties together:

1. Data Flows in Real Time

Every time an order is placed, inventory is updated, or a payment is processed, that data instantly updates across the entire system.

If a product ships out, accounting sees it, sales sees it, and the warehouse knows immediately — no lag, no duplicate entry.

2. Role-Based Access Keeps Things Secure

Each team or role gets access only to what they need. Warehouse staff can manage inventory. Finance handles ledgers. Executives see everything in summary.

Cloud ERPs like Kechie use enterprise-grade encryption and secure data centers to keep everything safe.

3. Modular Design Means Flexibility

You don’t have to buy everything at once.

Start with the core modules — like inventory, purchasing, and accounting — and add others (like CRM, manufacturing, or supply chain management) when you’re ready.

Kechie’s modular structure makes it easy to tailor the system to how your business actually works, not the other way around.

From Manual Processes to Real-Time Control

Let’s put this into perspective with a real-world scenario.

Say you’re a growing distributor managing three warehouses and hundreds of product SKUs. You rely on spreadsheets and a patchwork of legacy software to track orders, shipments, and inventory.

By the time your team reconciles the numbers, something’s already out of date.

Now imagine running all that through a cloud ERP like Kechie.

When an order comes in, inventory adjusts automatically. The purchasing module sees when it’s time to reorder. The warehouse gets pick-and-pack instructions instantly. Finance tracks the transaction in real time.

That’s not just automation — that’s control.

And it’s why distributors and manufacturers are embracing the cloud. They’re not just buying software; they’re building smarter, leaner operations.

Key Benefits of Cloud ERP (and Why They Matter)

1. Real-Time Insight for Faster Decisions

With a cloud ERP, you don’t wait for reports — you see everything as it happens. You know what’s selling, what’s stuck in production, and what needs attention.

That visibility helps leaders make proactive decisions instead of reactive ones.

2. Streamlined Inventory and Supply Chain Management

ERP systems like Kechie are designed for complex supply chains. They support FIFO tracking, barcode scanning, and serial number control. You can see exactly where every item is — from supplier to shelf — and plan production with confidence.

3. Lower Total Cost of Ownership

Forget about costly hardware or IT teams managing servers. With a subscription model, you pay for what you use and can scale up or down as needed.

No big upgrades, no surprise maintenance bills.

4. Seamless Integrations

Modern ERPs don’t exist in isolation. They integrate with your accounting, CRM, and eCommerce tools. For example, Kechie connects with systems like Shopify and QuickBooks Online, creating a unified data environment that saves time and prevents costly errors.

5. Security and Peace of Mind

Cloud ERP vendors invest heavily in cybersecurity. Your data is encrypted, backed up automatically, and stored in secure data centers — usually far more protected than an on-site server could ever be.

Migrating from On-Premise to Cloud: What to Expect

Moving to a new ERP system sounds intimidating, but it’s a lot smoother than most companies expect — especially when guided by experienced implementation partners.

Here’s what the process usually looks like:

1. Assess Your Current Systems — Identify what’s working, what isn’t, and where bottlenecks exist.

2. Set Clear Goals — Define what success looks like: faster order processing, better inventory accuracy, or improved reporting.

3. Plan Data Migration — Clean your data before importing it. It’s the best time to eliminate duplicates and outdated records.

4. Train Your Team — The best ERP is the one your team actually uses. Involve them early, provide role-based training, and gather feedback during rollout.

5. Go Live and Optimize — Once live, monitor performance and tweak workflows. With a cloud ERP like Kechie, updates and improvements are continuous.

The Future of ERP: Smart, Connected, and Data-Driven

ERP software isn’t just evolving — it’s transforming.

Here’s where things are headed:

- Artificial Intelligence (AI): Predictive analytics help forecast demand, optimize production schedules, and automate purchasing.

- IoT Connectivity: Machines and sensors feed live data directly into ERP systems for real-time monitoring.

- Automation Everywhere: From purchase orders to shipping notifications, manual tasks are being replaced by smart workflows.

- Deeper Customization: APIs allow businesses to connect ERP with specialized tools and build unique extensions.

Platforms like Kechie are already embedding these capabilities — making them not just management systems, but strategic growth engines.

Why Cloud ERP Is the Smartest Move for Growth

At some point, every growing manufacturer and distributor hits a wall — the one where spreadsheets, disconnected tools, and outdated systems start holding you back.

That’s when cloud ERP becomes more than a software choice. It becomes a growth strategy.

Cloud-based systems give you:

- Control of your entire operation in one place

- Real-time data to make better decisions

- Flexibility to scale without disruption

- Confidence that your technology will keep up with your ambition

In short, cloud ERP lets you focus on what you do best — building great products, delivering on time, and growing your business.

Final Thought

The businesses that thrive in the next decade won’t be the ones that work harder — they’ll be the ones that work smarter.

Cloud ERP solutions like Kechie make that possible by bringing together every piece of your operation into one intelligent, accessible system.

If your current tools are limiting your visibility or slowing your growth, it might be time to look at how cloud ERP can help you move faster, scale easier, and compete stronger.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

Kechie ERP- Turning Supply Chain Chaos into Clarity

Kechie ERP- Turning Supply Chain Chaos into Clarity

If you’ve ever had to tell a customer, “Sorry, we thought we had it in stock”, you know the pain of poor visibility. Maybe your system said you had 100 units, but the warehouse floor told a different story. Or a supplier missed a deadline, and you only found out when your production line came to a halt.

Sound familiar? For many companies, this is just business as usual when supply chains are run on spreadsheets and outdated systems. The problem is, with disruptions coming from every direction, those small cracks quickly turn into big headaches.

This is why more businesses are turning to Kechie ERP — a modern, cloud-based solution that doesn’t just patch problems but transforms the way supply chains operate.

Problem 1: Blind Spots Everywhere

You can’t fix what you can’t see. And without real-time data, supply chains are full of blind spots:

• Inventory counts that don’t match reality

• Supplier delays that catch you by surprise

• Shipments that vanish into a black hole of tracking numbers

These blind spots lead to rushed orders, costly mistakes, and frustrated customers.

Kechie’s Fix: Real-Time Visibility

Kechie ERP gives you a clear window into your supply chain, updated in real time. You can see:

• Inventory across all warehouses and locations

• Supplier performance and lead times

• Shipments as they move from dock to doorstep

• Customer demand as it happens

Instead of reacting after the fact, you’re in control from the start.

Problem 2: Inventory Inaccuracy & the Bullwhip Effect

One small miscalculation in demand can ripple through your supply chain like a whip — suppliers overproduce, warehouses overstock, and suddenly you’re sitting on piles of inventory you don’t need while running out of what customers actually want.

This bullwhip effect is a silent profit killer.

Kechie’s Fix: Smarter Inventory Management

Kechie ERP is built to stop the bullwhip effect in its tracks with:

• Configurable Cycle Counting — keep records accurate by scheduling counts by ABC code, item, category, or location.

• Forecasting & Analytics — use AI-driven insights to predict demand more accurately.

• Unified Data — connect sales, purchasing, and inventory so everyone sees the same numbers.

No more guesswork. No more overreactions. Just the right stock in the right place, at the right time.

Problem 3: Siloed Systems & Manual Work

In many organizations, finance, inventory, sales, and logistics all run on different platforms. Teams spend hours reconciling data, chasing errors, and trying to figure out which numbers are correct.

The result? Wasted time, duplicate work, and frustrated employees.

Kechie’s Fix: One Unified System

Kechie ERP replaces the patchwork of tools with one connected platform that covers:

• Inventory & Warehouse Management

• Procurement & Supplier Tracking

• Sales & Order Processing

• Logistics & Distribution

• Finance & Reporting

One login. One database. One version of the truth.

Problem 4: Customers Expect More

Today’s customers expect transparency. They want to know where their order is, when it will arrive, and why a delay happened. Businesses that can’t deliver that level of communication risk losing trust.

Kechie’s Fix: Reliable Customer Experiences

Kechie ERP helps you meet — and exceed — those expectations by:

• Providing real-time shipment updates

• Triggering alerts when problems arise

• Keeping products available when customers need them

• Building confidence with consistent, reliable service

When you communicate clearly and deliver consistently, customers stick around.

From Problems to Opportunities

Let’s be honest: disruptions aren’t going away. Supply chains will always face risks, sudden shifts, and rising expectations. The difference between businesses that struggle and those that thrive is the tools they use.

With Kechie ERP, the story changes:

• Blind spots turn into clear visibility

• Guesswork turns into accurate forecasting

• Silos turn into seamless integration

• Frustration turns into customer trust

Kechie doesn’t just solve problems. It gives you a competitive edge.

Next Steps: Still running your supply chain on spreadsheets or outdated systems? It’s time to see how Kechie ERP can give you the clarity, control, and confidence you’ve been missing.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!