What is Vendor Managed Inventory? How to Make VMI Work

Looking to streamline your supply chain and reduce inventory costs? You might want to look into Vendor-Managed Inventory (VMI). A VMI software might be the solution – as long as you know the best practices to make it work. So, what is VMI, and what is the impact on your business?

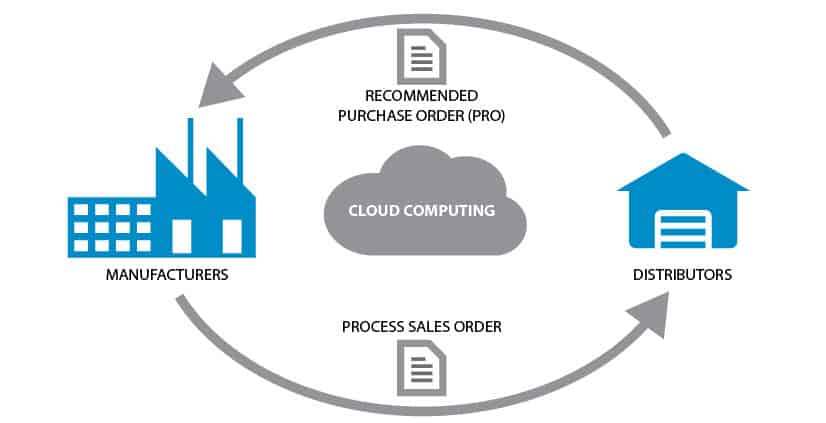

Vendor Managed Inventory is a business arrangement where the vendor of a product takes responsibility for making sure the buyer has the agreed inventory. The supplier or vendor ensures the stock is replenished automatically without the buyer’s initiation. If done right, VMI is a win-win situation for both the vendor and the customer.

What benefits can VMI bring to your business?

- VMI helps cut operating costs – With the supplier handling the quantity and frequency of orders, you can reduce costs associated with personnel and space.

- Lean inventory levels – VMI allows your vendors to supply in-demand goods at the right time. This also removes the need for safety stock.

- Improved Efficiency – The speed of stock replenishment is improved, and the risk of running out of stock is reduced. This improved service trickles down to the end-users.

What are the benefits of VMI for the Manufacturer/Supplier?

- Forecasting is easier courtesy of access to the buyer’s Point of Sale data.

- An optimized VMI program ensures you supply what is needed, and at the right time. Visibility to inventory levels helps the manufacturer ascertain the need for a product before it’s ordered.

- Produces a predictable and steady flow of income while mitigating the risk of losing the customer to a competitor.

- VMI reduces ordering errors and helps the supplier schedule operations productively

- A VMI program facilitates a stronger Customer-Supplier relationship. Both parties must work closely together to ensure seamless inventory management activities.

Cons of VMI

Regardless of the benefits highlighted above, enforcing a VMI program has a few drawbacks that business owners should keep in mind. One of the main disadvantages of VMI is its impact on sourcing. It’s difficult for supply chain managers to consider re-sourcing when the current VMI program is well-run. Some managers might be compelled to compromise supplier-related issues such as higher prices due to over-reliance on a vendor.

Granting non-employees full access to your inventory data is a significant risk. Leaving your stocking needs to the mercy of a 3rd party makes your business vulnerable to errors by the supplier, and even sabotage from competitors.

3 Steps to a Successful VMI Program

- Clarify expectations – and make them realistic: How will the system impact the supplier and the company? Both parties should be engaged in honest discussions to ensure everyone understands the risks and returns of the arrangement.

- Share information seamlessly: The success of a VMI program rests on the quality of information shared between the two parties. The supplier/manufacturer must have full visibility into the inventory levels to ensure a steady flow of goods.

- Clear and open communication: Constant and open communication is vital to the sustainability of the VMI business model. This includes discussing goals and progress towards achieving them. Each side must prevent a breakdown in communication, especially when miscues arise.

To make the best of vendor managed inventory, it’s important to utilize a complete inventory management solution to carry out all of the necessary steps on your behalf. Without insights into your inventory, it’s difficult to have automatic replenishment of vendor-managed inventory and timely invoicing. That’s why it’s important to utilize an inventory management solution like Kechie software, which allows you to set up, and streamline your VMI, to maintain automated operations between the vendor and all of the tracked inventory.