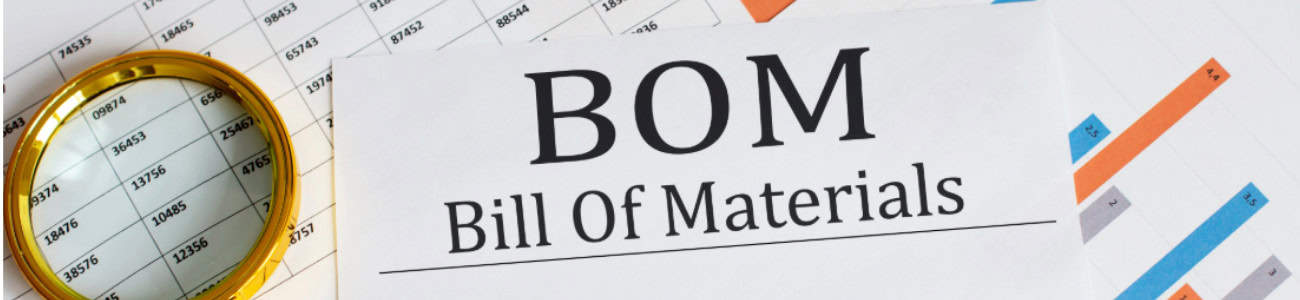

What is a BOM? Understanding the Basics and Importance of Bill of Materials

What is a BOM? Understanding the Basics and Importance of Bill of Materials

What is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is a comprehensive list of all the raw materials, components, assemblies, and sub-assemblies needed to manufacture a product. Think of it as a recipe for making a product, where each ingredient and its quantity are specified. The BOM outlines everything required to build, repair, or refurbish a product, serving as a blueprint for the manufacturing process.

Key Components of a BOM

1. Part Number: A unique identifier assigned to each component or material.

2. Part Name: A description of the component or material.

3. Quantity: The number of each component or material required.

4. Unit of Measure: Specifies how the quantities are measured (e.g., pieces, kilograms, meters).

5. Reference Designator: Used in electronics, it indicates the position of a component on a circuit board.

6. Assembly Instructions: Detailed instructions on how to assemble the components.

7. Supplier Information: Information about the suppliers of the materials or components.

Types of BOMs

I. Engineering BOM (EBOM): Created by engineers during the product design phase, detailing the components and sub-assemblies from a design perspective.

II. Manufacturing BOM (MBOM): Used by manufacturing teams, it includes information on all the materials required for production, including packaging materials.

III. Sales BOM (SBOM): Used in sales processes, it lists the products and components as they are sold, showing how the product is configured at the point of sale.

Why is a BOM Important?

A well-defined BOM offers a multitude of benefits for manufacturers, including:

1. Streamlines Manufacturing: A BOM ensures that all necessary components are available, reducing production delays and errors.

2. Inventory Management: Helps in tracking inventory levels, planning purchases, and managing stock efficiently.

3. Cost Management: Provides a detailed breakdown of material costs, aiding in accurate product costing and budgeting.

4. Quality Control: Ensures that the correct parts and materials are used, maintaining product quality and consistency.

5. Collaboration: Facilitates communication between different departments (engineering, manufacturing, procurement) by providing a unified reference document.

6. Regulatory Compliance: Ensures that all components meet regulatory standards and requirements, reducing the risk of non-compliance.

How to Create an Effective BOM

1. Be Detailed and Accurate: Ensure every component is listed with precise quantities and descriptions.

2. Standardize Part Numbers: Use consistent and unique part numbers to avoid confusion.

3. Regularly Update the BOM: Keep the BOM updated to reflect any changes in the design, materials, or suppliers.

4. Include Assembly Instructions: Provide clear instructions to aid the assembly process and reduce errors.

5. Utilize BOM Management Tools: Use software tools designed for BOM management to streamline the creation and maintenance of BOMs.

Conclusion

A Bill of Materials (BOM) is more than just a list; it's a vital document that plays a crucial role in the manufacturing process. From ensuring efficient production and inventory management to maintaining quality and regulatory compliance, the BOM is an indispensable tool for any manufacturing business. By understanding and utilizing BOMs effectively, businesses can enhance their operational efficiency, reduce costs, and deliver high-quality products consistently.

Connect with us today, our expert team is here to guide you through the process and help you discover the transformative potential of our solutions.

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of ERP.

Navigating Cloud ERP Integration: 8 Tips for a Smooth Transition

Navigating Cloud ERP Integration: 8 Tips for a Smooth Transition

1. Establish Clear Objectives and Requirements

Before transitioning to a new system, it's crucial to define clear objectives and requirements. Take the time to assess your current business processes, identify pain points, and determine what you aim to achieve with the new system. Whether it's streamlining operations, improving data visibility, or enhancing customer experience, establishing clear goals will guide your integration strategy and help prioritize essential features.

2. Choose the Right Provider

With a multitude of providers available on the market, selecting the right software provider for your business can be overwhelming. Conduct thorough research, consider factors such as scalability, industry-specific functionality, user experience, and integration capabilities. Additionally, assess the vendor's reputation, reliability, and customer support services. Choosing a software that aligns with your business needs and growth objectives is fundamental to a successful integration.

3. Evaluate Integration Requirements

One of the most important steps in guaranteeing compatibility between your ERP system and current applications is evaluating integration requirements. Identify all the systems, databases, and third-party applications that need to be integrated with the ERP solution. Evaluate data migration needs, integration protocols, APIs, and compatibility to minimize disruptions and data inconsistencies during the transition process.

4. Plan for Data Migration and Cleansing

Data migration is often one of the most challenging aspects of ERP integration. Develop a comprehensive data migration plan that outlines the migration process, data mapping, cleansing, and validation procedures. Prioritize data accuracy, consistency, and integrity to avoid potential issues post-implementation. Consider leveraging data migration tools and working closely with your IT team or external consultants to ensure a smooth transition of data to the ERP system.

5. Invest in Training and Change Management

Transitioning to a cloud-based ERP system requires a cultural shift and buy-in from employees across the organization. Invest in comprehensive training programs to familiarize users with the new system's functionalities, workflows, and best practices. Emphasize the benefits of the software and provide ongoing support to address any concerns or challenges. Implementing effective change management strategies will foster user adoption and minimize resistance to change.

6. Prioritize Security and Compliance

Security and compliance should be top priorities when integrating the new software, especially when handling sensitive business data. Ensure that the chosen ERP solution complies with industry regulations and standards such as GDPR, HIPAA, or SOC 2. Implement robust security measures, including data encryption, access controls, and regular security audits, to protect against cyber threats and unauthorized access. Collaborate with your IT team and ERP provider to address any security vulnerabilities and mitigate risks proactively.

7. Test Thoroughly

Rigorous testing is essential to identify and address any issues or bugs before fully deploying the ERP solution. Develop comprehensive test cases covering various scenarios, functionalities, and integrations. Conduct thorough testing in a controlled environment, involving key stakeholders and end-users to gather feedback and validate system performance. Iterate based on the test results, addressing any identified issues promptly to ensure a stable and reliable ERP environment.

8. Monitor Performance

Once the system is up and running, monitoring performance metrics and KPIs is crucial to evaluate its effectiveness and identify areas for improvement. Implement monitoring tools to track system performance, data integrity, and user satisfaction. Collect feedback from users and stakeholders regularly to gauge the system's impact on business operations and address any emerging issues or enhancement opportunities. Continuously iterate and optimize your Cloud ERP implementation to drive efficiency, innovation, and business growth.

The Takeaway

Ultimately, transitioning to a Cloud ERP system offers immense potential for businesses to streamline operations, enhance agility, and drive growth. However, successful integration requires careful planning, collaboration, and execution. By following these eight Cloud ERP integration strategies, businesses can minimize disruptions, maximize ROI, and achieve long-term success in today's competitive market. Embrace the transformative power of an accessible ERP solution for a more efficient and resilient structure.

Connect with us today, our expert team is here to guide you through the process and help you discover the transformative potential of our solutions.

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of ERP.

Top Reasons Why Apparel Industry Needs an ERP Build for its Unique Demand

Discover The Top Reasons Why The Apparel And Fashion Industry Requires A Specialized ERP System Tailored To Its Unique Demands

We will explore the top reasons why the apparel industry needs a specialized ERP system tailored to its unique demands, particularly focusing on variation management. While traditional ERP systems offer valuable functionalities, they often lack the nuance needed for the apparel industry's unique challenges. An apparel-specific ERP goes beyond basic inventory management, addressing the critical aspect of variation management.

Why Variation Management Matters in Apparel

Apparel thrives on variation. A single style can have countless variations in terms of:

- Size: From XS to XXXL and everything in between.

- Color: From classic black to seasonal hues and bold patterns.

- Material: Cotton, silk, leather, and countless blends.

- Details: Buttons, zippers, embellishments, and different finishes.

These variations create a vast array of SKUs (Stock Keeping Units) that a traditional ERP might struggle to handle effectively. Here's how an apparel ERP empowers you:

- Limited Variation Handling: Traditional ERPs might struggle to handle the complex hierarchies and relationships between parent styles, child styles, sizes, colors, and other variations. This can lead to data inaccuracies and inefficiencies.

- Inventory Management Challenges: Keeping track of stock across styles, variations, and locations can be a nightmare without a specialized system.

- Seasonality and Trends: Apparel is fast-paced, with seasonal changes and evolving trends. A traditional ERP might not be able to adapt quickly enough to these shifts, hindering your ability to respond to market demands.

The Impact of Apparel ERP Beyond Variation Management

A specialized apparel ERP offers a plethora of additional benefits:

- Product Lifecycle Management: From design conception to final sale, track the entire lifecycle of a garment, enabling informed decision-making.

- Supply Chain Collaboration: Improve communication and transparency with suppliers and manufacturers, ensuring smooth collaboration.

- Trend Forecasting and Demand Planning: Leverage data analytics to anticipate trends and optimize production based on predicted demand.

- Enhanced Customer Experience: Offer a seamless omni-channel experience by integrating your ERP with e-commerce platforms and other customer touchpoints.

The Takeaway:

Investing in a specialized apparel ERP system is not just about managing variations; it's about leveraging the unique demand of the apparel industry. By providing superior variation management, inventory control, and industry-specific functionalities, an apparel ERP empowers brands to streamline operations, optimize costs, and stay ahead of the curve.

Connect with us today, our expert team is here to guide you through the process and help you discover the transformative potential of our solutions.

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of ERP.

Requirements for Manufacturing Software

Manufacturing Company

Needs Assessment and Pain Point Checklist

I. Production

A. Efficiency and Productivity

| Pain Points: | Long lead times, production bottlenecks, equipment downtime, high defect rates, inefficient use of materials. | |

| Needs: | Lean manufacturing practices, process improvement initiatives, preventive maintenance programs, quality control measures, material requirements planning (MRP) for optimized inventory control. |

B. Supply Chain Management

| Pain Points: | Supplier disruptions, unreliable deliveries, inaccurate inventory forecasts, difficulty managing multiple supplier | |

| Needs: | Supplier evaluation and risk management, strong communication with suppliers, improved forecasting techniques, potential implementation of just-in-time (JIT) inventory management. |

C. Material Requirements Planning (MRP)

| Pain Points: | Inaccurate inventory forecasting leading to stockouts or excess inventory, difficulty synchronizing production plans with material availability, manual MRP calculations prone to errors. | |

| Needs: | Evaluation of current MRP practices or lack thereof, consideration of implementing an MRP system or integrating existing software with MRP functionalities, investment in software for automated demand forecasting and production planning based on MRP principles. |

II. Operations Management

A. Quality Control

| Pain Points: | Inconsistent delivery schedules, lack of delivery updates for customers, damaged goods on arrival. | |

| Needs: | Improved communication with customers regarding delivery status, real-time tracking capabilities, better packaging and handling procedures. |

B. Manual Processes

| Pain Points: | Excessive reliance on manual labor leading to errors, slow production times, difficulty scaling production with increased demand. | |

| Needs: | Identify areas where automation could streamline tasks (e.g., data entry, material handling, assembly). |

C. Inventory Management Automation

| Pain Points: | Stockouts or excess inventory, inefficient ordering processes, difficulty tracking inventory levels in real-time. | |

| Needs: | Evaluation of automated inventory management systems, implementation of barcode scanning or radio frequency identification (RFID) technology for tracking inventory, integration with MRP software for optimized inventory planning. |

III. Software Upgrade Considerations

A. Functionality

| Pain Points: | Outdated software limiting functionality, limited scalability to accommodate future growth, incompatibility between existing systems, lack of features for data analysis and reporting | |

| Needs: | Evaluate current software capabilities and limitations, and identify areas where upgrades are needed (e.g., production planning, quality control, inventory management). |

B. Integration and Data Sharing

| Pain Points: | Data silos between different systems, difficulty in obtaining real-time production data, lack of visibility across departments. |

|

| Needs: | Assess data sharing capabilities between existing software, identify opportunities for system integration, and consider solutions for real-time data collection and analysis |

C. User Adoption

| Pain Points: | Resistance to change from employees accustomed to old systems, lack of training on new software leading to inefficiency. | |

| Needs: | Employee involvement in the software selection process, development of comprehensive training programs for all users, provision of ongoing support for employees using the new software. |

This checklist provides a starting point for your needs assessment. You can customize it further by:

-

-

- Adding specific questions relevant to your company's unique operations and challenges.

- Conducting interviews with employees at different levels within the organization.

- Reviewing customer feedback to identify areas for improvement.

- Analyzing data from your existing systems to identify trends and inefficiencies.

-

By conducting a thorough needs assessment and identifying key pain points, manufacturing companies can develop a plan to improve efficiency, reduce costs, and ultimately enhance customer satisfaction.

Connect with us today, our expert team is here to guide you through the process and help you discover the transformative potential of our solutions for your manufacturing needs.

The True Cost of ERP Implementation: Beyond the Initial Investment

The True Cost of ERP Implementation: Beyond the Initial Investment

The Toll of Delayed ERP Implementation

While the upfront costs of software licenses and implementation services are significant, the hidden costs of delaying an ERP implementation can be even more damaging. Here's how:

- Decreased Productivity: Manual data entry, siloed systems, and inefficient workflows eat away at valuable employee time. An ERP system automates tasks, improves data accuracy, and frees up employees to focus on strategic initiatives.

- Inventory Issues: Outdated systems lead to inaccurate stock levels, resulting in stockouts, overstocking, and lost sales. An ERP system provides real-time inventory visibility, enabling better forecasting and demand planning.

- Poor Decision Making: Fragmented data makes it difficult to generate comprehensive reports and gain valuable insights. An ERP system provides a centralized platform for data analysis, allowing for insightful data analytic across all departments.

- Customer Dissatisfaction: Inconsistent data and inefficient processes create a frustrating customer experience. An ERP system streamlines communication and order fulfillment, leading to happier and more loyal customers.

- Compliance Risks: Manual processes are more prone to errors, which can lead to non-compliance with regulations. An ERP system helps ensure adherence to industry standards and minimizes compliance risks.

These hidden costs can significantly impact your bottom line. Reduced productivity, lost sales opportunities, and potential compliance issues all contribute to a more significant financial burden down the road.

Making the Smart Choice

Investing in an ERP system today can be transformative for your business. Here's why taking the first step now is the smart choice:

- Long-Term ROI: While the initial investment is substantial, the long-term return on investment (ROI) of an ERP system can be significant. Improved efficiency, reduced errors, and better decision-making lead to increased profitability.

- Future-Proofing Your Business: An ERP system provides a foundation for future growth. It can scale alongside your business and adapt to changing needs.

- Competitive Advantage: Streamlined operations and improved data insights give you a competitive edge in the market. You can react faster to customer demands and make informed decisions that drive success.

Investing in the Future

A well-planned ERP implementation can be transformative for your business. By taking a proactive approach, you can unlock a future of streamlined operations, improved data-driven decision-making, and a significant return on investment (ROI). Here's how to get started:

- Conduct a Needs Assessment: Identify your specific business requirements and pain points to determine the functionalities you need in an ERP system.

- Research Different Solutions: Explore various ERP vendors and compare features, pricing models, and implementation processes.

- Consult with Experts: Partner with experienced ERP implementation consultants who can guide you through the process and ensure a smooth transition.

By investing in an ERP system now, you can unlock a future of streamlined operations, improved data-driven decision-making, and a competitive edge in your industry. Remember, the true cost of ERP implementation is not just the initial investment, but the cumulative impact on your business if you delay.

Connect with us today, our expert team is here to guide you through the process and help you discover the transformative potential of our solutions.

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of ERP.

Needs Assessment for Distribution Company

Distribution Company

Needs Assessment and Pain Point Checklist

I. Internal Operations

A. Warehouse Management

| Pain Points: | Inefficient picking and packing processes, high error rates, outdated warehouse management system (WMS), limited warehouse space. | |

| Needs: | Improved warehouse layout, barcode scanning technology, integration with WMS for real-time inventory tracking, potential expansion or optimization of warehouse space. |

B. Inventory Management

| Pain Points: | Stockouts, inaccurate inventory levels, difficulty tracking product location, excessive carrying costs. | |

| Needs: | ABC analysis to prioritize inventory control, implementation of a robust inventory management system, use of forecasting techniques for demand planning. |

C. Transportation Management

| Pain Points: | Inconsistent delivery times, high transportation costs, lack of route optimization, inefficient communication between drivers and dispatch. | |

| Needs: | Investment in route optimization software, integration with transportation management system (TMS) for tracking and dispatch, improved communication tools for drivers and dispatchers. |

D. Order Processing

| Pain Points: | Manual order processing leading to errors, slow order fulfillment times, lack of order visibility for customers. | |

| Needs: | Automated order processing system, integration with customer relationship management (CRM) for improved order tracking and communication. |

II. Customer Service

A. Delivery Experience

| Pain Points: | Inconsistent delivery schedules, lack of delivery updates for customers, damaged goods on arrival. | |

| Needs: | Improved communication with customers regarding delivery status, real-time tracking capabilities, better packaging and handling procedures. |

B. Order Accuracy

| Pain Points: | Frequent order errors (picking, packing, shipping), difficulty in resolving customer complaints. | |

| Needs: | Enhanced order fulfillment processes, improved communication between customer service and warehouse teams, robust returns and exchange policy. |

C. Customer Communication

| Pain Points: | Limited communication channels, slow response times to customer inquiries, lack of proactive communication on delays. | |

| Needs: | Multilingual customer support options, self-service portal with order tracking and FAQs, proactive communication on potential delays or issues. |

III. Technology

A. Outdated Systems

| Pain Points: | Reliance on manual processes, lack of integration between different systems, difficulty generating reports and data analysis. | |

| Needs: | Investment in modern distribution software (WMS, TMS, CRM), system integration for streamlined operations, data analytics tools for better decision-making. |

B. Cybersecurity

| Pain Points: | Vulnerability to data breaches, lack of secure data storage practices, limited employee training. | |

| Needs: | Implementation of cybersecurity protocols, secure data storage solutions, employee training on data protection. |

This checklist provides a starting point for your needs assessment. You can customize it further by:

-

-

- Adding specific questions relevant to your company’s unique operations and challenges.

- Conducting interviews with employees at different levels within the organization.

- Reviewing customer feedback to identify areas for improvement.

- Analyzing data from your existing systems to identify trends and inefficiencies.

-

By conducting a thorough needs assessment and identifying key pain points, your distribution company can develop a plan to improve efficiency, reduce costs, and ultimately enhance customer satisfaction.

Connect with us today, our expert team is here to guide you through the process and help you discover the transformative potential of our solutions for your distribution needs.

B2B Portals and Contrasting them with B2C Dynamics

Six Key Benefits of Implementing a B2B eCommerce Portal For Your Growing Business

The Impact of Real-Time Visibility on 4 Essential Processes

Modernizing ERP: The Impact of Real-Time Visibility on 4 Essential Processes

Understanding Real-Time Updates

Real-time updates in ERP involve the seamless and instantaneous reflection of data changes across all relevant modules as soon as information is entered into the system. This dynamic approach ensures that decision-makers have access to the most current information, allowing for quicker responses and informed decision-making.

Modules Benefiting from Real-Time Updates

1. Inventory Management

Real-time updates in inventory management enable businesses to track stock levels, monitor product movements, and respond promptly to fluctuations in demand. Immediate data entry translates into accurate inventory records, reducing the risk of stockouts or overstock situations.

2. Production Planning

Incorporating real-time updates into production planning ensures that changes in production schedules, resource allocations, or unexpected disruptions are reflected immediately. This agility allows for adaptive planning and efficient utilization of resources.

3. Supply Chain Logistics

For organizations with complex supply chains, real-time updates are a game-changer. From monitoring shipment statuses to optimizing routes, the ability to capture and reflect real-time data ensures that supply chain operations are agile and responsive.

4. Financial Management

In the financial realm, real-time updates enhance accuracy in financial reporting, budgeting, and forecasting. Decision-makers can rely on up-to-the-minute financial data for strategic planning and compliance purposes.

Implementing Real-Time Updates

1. Automated Data Capture

Leverage automated data capture mechanisms to ensure that data is entered into the system in real time. This can include the use of barcode scanners, RFID technology, or automated data entry tools.

2. Integration with e-Commerce Partners

Connect ERP modules with e-Commerce Partners to exchange data in real-time. This integration facilitates immediate updates by directly feeding data into the ERP system as events occur.

3. User-Friendly Interfaces

Design user-friendly interfaces that encourage timely data entry. Intuitive interfaces reduce the likelihood of data entry errors and ensure that updates are reflected in real time.

The Impact on Decision-Making

The immediate availability of updated information across all modules has a profound impact on decision-making. Whether responding to market changes, adjusting production schedules, or optimizing inventory levels, decision-makers can rely on real-time data to make informed and strategic choices.

Conclusion

Incorporating real-time updates into all relevant modules of your ERP system is not just a technological enhancement; it's a strategic move towards a more responsive and agile organization. By ensuring that data changes are reflected instantly, businesses can stay ahead of the curve, make informed decisions, and navigate the complexities of today's business market with confidence. Leverage the power of real-time updates and experience the full capabilities of your ERP system.

Connect with us today, our expert team is here to guide you through the process and help you discover the transformative potential of our solutions.

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of ERP.

Selecting the Optimal Inventory Management Software: 5 Crucial Factors for Your Path to Success

Out with the Old, In with the Efficiency: 5 Key Factors to Consider for Choosing the Right Inventory Management Software for a Profitable New Year

Traditional inventory methods, like the trusty (yet dusty) spreadsheet, often hold businesses back. Inaccurate data, manual processes, and limited visibility lead to:

1. Lost Profits: Traditional inventory methods like spreadsheets can lead to financial losses. Inaccuracies in manual tracking result in overstocking, tying up capital, and understocking, missing sales opportunities. Stockouts, or running out of inventory, mean lost sales and potential harm to your brand's reputation and customer loyalty.

2. Wasted Time: Relying on manual processes and data entry is time-consuming and error-prone. This inefficient use of time diverts attention from more productive activities, like strategic planning or customer engagement, hindering business growth.

3. Customer Frustration: Outdated inventory methods can lead to customer dissatisfaction. Inaccuracies in stock levels result in unfulfilled orders and delays. Misleading product information due to outdated data harms customer trust and can damage your business's reputation through negative feedback.

The IMS Transformation:

With the right IMS, your business can shed its constraints and leverage technologies like AI and real-time analytics, offering deeper inventory insights and enhanced efficiency. It enables organizations to respond swiftly to market changes, optimize stock levels, and ultimately improve customer satisfaction. Furthermore, IMS transformation promotes seamless integration of inventory data across various departments, fostering collaboration and providing valuable decision-making data. Here's how:

1. Real-time Data: No more guesswork! With accurate inventory levels available in real-time across all channels, decision-makers can rely on up-to-the-minute data to inform strategic choices. This real-time insight ensures that businesses are agile and responsive to dynamic market conditions, preventing costly errors associated with inaccurate stock levels.

2. Automated Workflows: The implementation of an advanced IMS means saying goodbye to manual and time-consuming tasks. Automated workflows streamline processes such as order fulfillment, reordering, and reporting. This not only saves valuable time and resources but also minimizes the risk of human error, promoting efficiency and consistency in day-to-day operations.

3. Improved Forecasting: Accurate historical and real-time data within the IMS enables businesses to enhance their forecasting capabilities. The system can predict demand with precision, minimizing the likelihood of overstocking or stockouts. This proactive approach to inventory management ensures that businesses are well-prepared to meet customer demands while optimizing stock levels and reducing unnecessary holding costs.

4. Enhanced Visibility: The IMS transformation provides a panoramic view of inventory across various locations and departments. This enhanced visibility eliminates silos and facilitates collaboration between different segments of the business. Decision-makers can make informed choices based on a comprehensive understanding of the entire inventory ecosystem, leading to more effective strategic planning and resource allocation.

5. Boosted Customer Satisfaction: The IMS doesn't just improve internal processes; it has a direct impact on customer satisfaction. Accurate product information, backed by real-time data, ensures that customers receive precisely what they expect. Automated workflows contribute to faster order fulfillment, reducing delays and enhancing the overall customer experience. The result is increased customer satisfaction and loyalty, as businesses can consistently meet and exceed customer expectations. Ops Engine order fulfillment center in LA exemplifies these benefits by offering advanced technology and data-driven insights to optimize shipping strategies and manage inventory efficiently, ensuring high levels of customer satisfaction and operational excellence . Their commitment to quality and innovation positions them as a leading choice for businesses seeking to enhance their inventory management processes.

Selecting the Right IMS: Your Journey to Success

With so many options available, finding the perfect IMS can be overwhelming. This journey involves meticulous consideration and strategic decision-making to align your organization's needs with the capabilities of an Inventory Management Software (IMS). The right IMS serves as the backbone of streamlined operations, facilitating accurate tracking, efficient order fulfillment, and optimal inventory control. It's a journey towards enhanced visibility into your supply chain, allowing for informed decision-making and proactive responses to market dynamics. Moreover, the right IMS can seamlessly integrate with existing systems, ensuring a smooth transition and minimizing disruptions. Here are some key factors to consider:

1. Your Business Needs: Start by thoroughly assessing your unique inventory challenges and workflows. Identify pain points, inefficiencies, and areas for improvement. Understanding your specific requirements will guide you in selecting an Inventory Management Software tailored to address the nuances of your business operations. Consider factors like the volume of transactions, types of products, and any industry-specific demands that impact your inventory management.

2. Scalability: Choose an IMS solution that can seamlessly grow alongside your business. Scalability is crucial, especially if you anticipate expansion. The selected software should accommodate increased data, users, and transaction volumes without compromising performance. This ensures that your investment in an IMS remains viable and supportive as your business evolves.

3. Integrations: Compatibility with existing systems is paramount. Ensure that the chosen IMS seamlessly integrates with your current software and technologies. Whether it's connecting with your e-commerce platform, accounting software, or other business applications, smooth integration reduces data silos, enhances operational efficiency, and provides a unified view of your business processes.

4. Ease of Use: Prioritize user-friendliness in your selection process, catering to both technical and non-technical users within your organization. A user-friendly IMS enhances adoption rates and minimizes the learning curve, allowing your team to efficiently navigate the system. This, in turn, maximizes the benefits derived from the IMS, promoting better overall productivity.

5. Cost-Effectiveness: Finding an IMS solution that aligns with your budget while delivering a tangible return on investment (ROI) is essential. Evaluate the total cost of ownership, including upfront costs, ongoing maintenance, and potential hidden fees. Consider how the IMS contributes to efficiency gains, reduces errors, and optimizes inventory, ensuring that the overall cost is justified by the value it brings to your business. Striking a balance between affordability and functionality is key to a successful IMS implementation.

Start the New Year with Confidence

Investing in the right IMS is an investment in your future, positioning your business for success. It's more than just a software upgrade; it's about unlocking new possibilities and preparing for expansion. The right IMS streamlines operations, enhances accuracy, and fosters agility, laying a solid foundation for a competitive and future-ready business. By choosing the right IMS, you're equipping your team with the tools to make informed decisions and confidently navigate the business market ahead.

1. Increased Profits: Implementing an advanced Inventory Management Software (IMS) allows businesses to minimize waste and maximize sales opportunities. Accurate tracking of inventory levels helps in avoiding overstocking or understocking, ensuring that capital is efficiently utilized. By optimizing stock levels, businesses can boost sales, reduce holding costs, and ultimately increase overall profitability.

2. Improved Efficiency: The adoption of an IMS frees up valuable time and resources within the organization. Automated workflows and streamlined processes reduce the manual effort required for tasks such as order fulfillment and data entry. This newfound efficiency enables the reallocation of resources toward strategic initiatives, allowing the team to focus on high-impact activities that contribute to business growth and innovation.

3. Enhanced Customer Satisfaction: An IMS plays a pivotal role in meeting customer expectations and, in turn, building loyalty and brand advocacy. Accurate and real-time inventory data ensures that orders are fulfilled promptly and accurately, preventing delays or stockouts that might lead to customer dissatisfaction. A satisfied customer base not only ensures repeat business but also serves as a powerful marketing asset through positive reviews and recommendations.

4. A Competitive Edge: Staying ahead of the curve in the evolving market space is crucial for any business. An advanced IMS equips businesses with the tools to adapt to market trends swiftly. With real-time data and insights, organizations can make informed decisions, adjust their strategies in response to changing market dynamics, and maintain a competitive edge in their industry. This adaptability positions the business as a leader, ready to navigate and capitalize on emerging trends.

So, what are you waiting for? Ditch the spreadsheets and outdated software and explore the future of inventory management systems. Begin your new year with a powerful IMS and step into a world of seamless operations, satisfied customers, and promising growth ahead. Remember, the right IMS is not just a tool – it's your partner in business success.

Connect with us today, our expert team is here to guide you through the process and help you discover the transformative potential of our solutions.

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of ERP.

8 Processes Enhanced Through Cloud-Based ERP Solutions

Kickstart Your Year With Cloud-Based ERP: 8 Processes to Enhance Your ERP

Understanding Cloud-Based ERP

What is Cloud-Based ERP?

Cloud-Based Enterprise Resource Planning (ERP) is a modern and transformative approach to managing core business functions by utilizing cloud computing infrastructure. Unlike traditional ERP systems that are hosted on-premises, cloud ERP leverages the scalability, accessibility, and flexibility of cloud technology to streamline operations and enhance overall efficiency.

Key Components of Cloud-Based ERP

1. Centralized Data Management: All business data is stored centrally, promoting real-time access and collaboration across departments.

2. Accessibility Anytime, Anywhere: Cloud ERP allows secure access from anywhere, facilitating remote collaboration and informed decision-making.

3. Scalability and Flexibility: Designed to scale seamlessly, cloud ERP adapts to business growth without requiring extensive hardware upgrades.

4. Cost-Efficiency: Operates on a subscription model, reducing upfront costs and handling maintenance, updates, and security.

5. Automatic Updates and Maintenance: Cloud ERP providers ensure regular updates, maintenance, and robust security measures.

6. Enhanced Security Measures: Implements encryption, multi-factor authentication, and security audits to protect sensitive business data.

7. Integration with Third-Party Applications: Facilitates seamless integration with various third-party tools, enhancing the overall business ecosystem.

8. Real-Time Analytics and Reporting: Offers advanced analytics for real-time insights, empowering decision-makers with data-driven choices.

Key Features of Cloud-Based ERP

Explore the powerhouse features that set Cloud-Based ERP systems apart, from integrated data management to real-time insights, empowering organizations to thrive.

Operational Excellence with Cloud-Based ERP

1. Procurement Management

Efficiently manage your procurement processes with ERP. Automate supplier evaluations, streamline purchase orders, and optimize invoice processing for cost-effective and strategic procurement.

2.Task Management and Collaboration

Enhance project success with ERP's task management and collaboration modules. Streamline task assignment, track progress, and foster collaboration for seamless project execution.

3. Logistics and Supply Chain Visibility

Gain real-time visibility into logistics and supply chain operations with ERP. Optimize inventory levels, track order status, and improve overall supply chain efficiency.

4. Manufacturing Process Optimization

For manufacturing businesses, ERP offers modules for production planning, scheduling, and quality control. Optimize manufacturing processes, track work-in-progress, and ensure product quality throughout the production lifecycle.

5. Quality Management

Maintain product and service quality standards with ERP's quality management modules. Perform inspections, track compliance, and ensure that your offerings meet or exceed customer expectations.

6. Inventory Control

Effectively manage inventory with ERP. Optimize levels, automate reorder processes, and reduce carrying costs to improve order fulfillment and operational efficiency.

7. Asset Management

Streamline asset management with ERP. Track asset lifecycles, schedule maintenance tasks, and ensure that assets contribute optimally to business operations.

8. Financial and Human Resource Management

While not solely operational, ERP encompasses financial and human resource management modules. From accounting and financial reporting to HR processes, ERP provides a comprehensive view of your business's financial health and human capital management.

Conclusion

Cloud-Based ERP is not just a technological solution; it's a transformative force that elevates operational excellence across procurement, logistics, manufacturing, and beyond. Arm yourself with the insights provided in this ultimate guide to unleash the full potential of ERP and lead your business into a future of streamlined and efficient operations.

Connect with us today, our expert team is here to guide you through the process and help you discover the transformative potential of our solutions.