ERP Implementation

Why We Go Deep on ERP Implementation—and Why It Pays Off

ERP failures don’t usually happen because of bad software. They happen because of poor implementation. Rushed planning. Dirty data. Processes that don’t align. And teams left to “figure it out” on their own.

That’s why at My Office Apps, we don’t treat implementation like a one-week setup call. We treat it like the strategic phase it is. We get involved early, ask the hard questions, and stay with you until the system is running the way your business runs.

Here’s why that approach works—and what you gain by getting it right from day one.

We Start With Your Reality, Not Just Our Software

Most ERP vendors lead with features. We start with your operations.

Before a single module is configured, we work with your team to map how your business actually works—from purchasing and inventory to production and finance. That means understanding not just your ideal workflows, but the messy, real-world stuff too.

Why? Because software should fit the business—not the other way around.

We Operate on Best Practices—Even When It’s Hard

You’re hiring us for expertise, not just a tool. That’s why we don’t just replicate broken processes or take shortcuts to meet an arbitrary deadline.

We implement based on industry best practices—period. Even when that means slowing down, challenging assumptions, or untangling legacy workarounds.

Because long-term success starts with getting the fundamentals right, not going live fast and hoping for the best.

Clean Data Isn’t Optional—It’s Foundational

Bad data leads to bad decisions. Full stop. So we don’t just migrate your existing files—we clean them. That includes:

- Removing duplicates and inactive records

- Standardizing naming conventions and units of measure

- Mapping fields correctly between legacy systems and Kechie

If your ERP goes live with bad data, it becomes a source of confusion. When it's clean, it becomes a trusted source of truth. That’s a difference your team will feel immediately.

Sandbox Training: Learn in Your Environment, Not Ours

Training in a generic demo environment doesn’t reflect how your business works. That’s why every Kechie implementation includes access to a sandbox—a safe, fully-configured replica of your system where your team can practice using your actual data, processes, and structure.

Why it matters:

- Users build muscle memory with real scenarios—not simulations

- Teams can test workflows and catch issues before go-live

- Managers gain confidence that everything’s configured correctly

This approach makes the transition smoother and dramatically improves adoption. When users train in their own environment, they’re not just prepared—they’re confident.

We Build the System With You, Not For You

Every Kechie implementation is collaborative. We configure the platform to match your business rules, approval flows, and reporting needs—not just drop in standard templates.

We also include:

- Role-based access setup

- Automated workflows tailored to your process

- Reports and dashboards that match your KPIs

This ensures your team logs in on day one and sees a system that feels familiar, helpful, and built for them.

Training Isn’t a PowerPoint Deck

We train teams based on how they actually use the system. That means:

- Hands-on, role-specific sessions

- Real-world tasks, not hypothetical demos

- Clear documentation and support post-launch

Your warehouse lead doesn’t need to know the finance module. And your CFO doesn’t want to be trained on receiving workflows. We respect your time—and we train accordingly.

Fixing It Later Is Way More Expensive

Cutting corners during ERP implementation almost always leads to rework. And rework is costly. Downtime, retraining, lost trust—it adds up.

By investing in the right setup now, you get:

- Faster user adoption

- More accurate reporting

- Fewer support tickets

- A system that scales cleanly as you grow

Bottom line: you only get one chance at a clean start. We make sure you use it well.

Final Thought: Implementation Isn’t a Phase. It’s the Foundation.

A great ERP is only as good as its implementation. That’s why we treat this part of the process with the depth and discipline it deserves. We follow best practices—not shortcuts. We train your people in your system. And we do the heavy lifting upfront so you don’t face costly fixes later.

We take pride in getting it right the first time, investing the time and resources needed to set up every client for long-term success.

Because doing it right isn’t always easy—but it always pays off.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of an ERP.

Multi-Warehouse Inventory Control While Short-Staffed

Keep Your Multi-Warehouse Inventory Synced While Short-Staffed

Managing inventory across multiple warehouse locations is already challenging. Add a short-staffed team to the mix—due to summer vacations, turnover, or hiring delays—and things can get messy fast.

That’s where Kechie ERP comes in. Its cloud-based, integrated approach makes it easy to stay in control of distributed inventory without relying on tribal knowledge or daily micromanagement.

If you’re an operations leader facing reduced headcount, here’s how you keep warehouses aligned without skipping a beat.

Real-Time Visibility Across All Locations

When staff are spread thin, you don’t have time to call, email, or ping for updates. You need one place to see:

-

- What’s in stock

- What’s in transit

- What’s running low

Kechie ERP’s multi-warehouse module gives you full visibility in real time, across every site. You can sort by location, category, quantity, or custom fields—so you’re not guessing which warehouse has what.

Automated Transfers and Replenishment

When demand shifts or one location is low, you don’t need a manual chase.

With Kechie ERP, you can:

-

- Set auto-replenishment rules between warehouses

- Define safety stock thresholds per site

- Schedule inter-warehouse transfers based on real usage

Access From Anywhere, Without the IT Wait

If your warehouse manager is out, or someone needs to check on inventory remotely, Kechie makes it easy. No VPNs. No local installs. No lag.

Because Kechie ERP is fully cloud-based and mobile-friendly, any authorized team member can:

-

- Check stock status

- Approve a transfer

- Monitor receiving or shipping logs

You stay agile even when your staff isn’t all under one roof—or available on-site.

Role-Based Access and Error Reduction

Short-staffed teams often rely on temps or floaters from other departments. That can create risk if systems are hard to use or too open.

Kechie allows you to:

-

- Control who can view or edit each location

- Automate common tasks to reduce manual input

- Track all activity for full traceability

Fewer errors, tighter control—and no lost time fixing data after-the-fact.

Consolidated Reporting for Faster Decisions

When you’re short on time and people, long reports are useless. You need clean data and fast answers.

Kechie ERP’s reports are:

-

- Drillable by warehouse, product, or time period

- Exportable for team meetings or financial roll-ups

- Customizable without developer help

This helps you prioritize and respond faster, whether it’s a transfer, reorder, or process change.

Make It Easier for Your Team to Succeed—Even With Less Help

Short-staffed doesn’t have to mean out of sync. With Kechie ERP, you’re not relying on memory, paper logs, or luck to keep inventory aligned across locations. You’re using live data, rules-based automation, and built-in flexibility to operate smarter.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of an ERP.

Top 5 Reasons Our Customers Love Kechie ERP

5 Reasons Our Customers Love Kechie ERP

At My Office Apps (MOA), we don’t just deliver software—we provide real solutions built around our customers’ needs. And while we’re proud of our software, the most meaningful feedback comes directly from the businesses that rely on us daily. Their success stories are the best proof of the value we bring.

Here are the top five reasons our customers love using Kechie ERP:

1. It’s Easy to Use—Even for Non-Tech Teams

ERP systems have a reputation for being complicated, clunky, and difficult to implement. Kechie ERP breaks that mold. Designed with simplicity in mind, our platform offers an intuitive user experience that makes it easy for anyone—regardless of technical background—to learn and use.

From the start, we guide you through a fully managed onboarding process. We handle your data migration, train your team through weekly online meetings, and customize the system based on how your business actually works. And unlike many ERP vendors, we don’t pass you off to a third-party implementer. You’ll work directly with our team from day one and with ongoing support even after implementation is complete.

Whether your warehouse staff is managing inventory or your accounting team is generating reports, Kechie’s clean interface, customizable dashboards, and streamlined workflows make it easy to get things done quickly and accurately.

“The system is user-friendly, accommodating even our less tech-savvy team members. The ease of use and a noticeable increase in sales revenue confirm that investing in this system is entirely worthwhile.”

– Sales Manager, Retail Company

“We are very happy with this software. It is user-friendly, direct and easy to use for anyone even if they are not tech savvy. This program allows us to pack & ship and to keep inventory.”

– Operations Manager, Electrical Manufacturing Company

2. Responsive, Knowledgeable Customer Support That Feels Like a Partner

ERP software is only as good as the support behind it. At MOA, we take customer support seriously—because we know the stakes are high when it comes to running your business.

Our U.S.-based support team is known for its fast response times, deep product knowledge, and genuine commitment to client success. We don’t just answer tickets—we roll up our sleeves and work alongside you to solve problems, optimize workflows, and ensure you’re getting the most out of your investment.

During implementation, we make sure you feel supported every step of the way. After go-live, we continue to be available with responsive support, ongoing training, and proactive solutions tailored to your needs. Whether you’re requesting a customization, learning a new feature, or troubleshooting a process, we’re right there with you.

“It has been very user friendly and the team was great in training and answering our questions during implementation. The customer support is great and in the U.S.”

– Management, Non-Profit Organization

“The team at Kechie have made it so easy for us by their continuous support and helping us with modifications on the software to make it a bespoke ERP that fits us 100%. The support is extremely helpful and responsive.”

– Operations, Ice Cream Manufacturer and Distributor

3. Incredible Value for Money

Too many companies have been burned by ERP systems that overpromise, underdeliver, and come with massive price tags. Kechie ERP offers a refreshing alternative—robust functionality at a fair, transparent price.

We believe in delivering enterprise-grade features without locking businesses into bloated, overpriced systems. Our flexible pricing structure is built with scalability in mind, allowing you to add capabilities as you grow. No hidden fees, no nickel-and-diming—just powerful tools that help you run your business better.

For our customers, the value is clear. Many have saved thousands after switching from legacy or overbuilt systems, while gaining greater efficiency, accuracy, and control.

“Kechie isn't only an incredibly feature-rich ERP application, it's affordable and backed by an account management, project management, and development team that is second to none!”

– Operations, Consumer Goods Company

“The problems that we had with our previous ERP was the cost being too high compared with the benefits and functions our company needed. With Kechie, the cost savings are significant while we also satisfy our company’s needs.”

– Operations, IT and Services Company

4. Functionality That Solves Real-World Problems

A great ERP system should make your life easier—not more complicated. That’s why we designed Kechie ERP to focus on the core functionalities growing businesses truly need, with the ability to scale and adapt as those needs evolve.

Whether it’s inventory management, purchasing, accounting, CRM, sales, reporting, or batch tracking—every module is built to work together in one cohesive ecosystem. You don’t need to be a tech expert to benefit from automated invoicing, real-time financial reports, or integrated workflows that eliminate repetitive manual tasks.

Kechie streamlines complex processes, reduces human error, and gives you accurate insights so you can make better decisions, faster.

“Ease of use and lots of automation. Integrated accounting and financial reports.”

– Operations, Accounting Client

“Not only did Kechie help set us up for success, but the team has been amazing! They have been with us from the beginning of the process, until we went live… We are the first Donation Center in the City to have an Inventory Management system that maintains the data and integrity—and we owe it to Kechie.”

– Management, Non-Profit Organization

5. It’s a True All-in-One Solution That Connects Everything

Juggling disconnected systems, spreadsheets, and third-party tools slows your business down. Kechie ERP eliminates that chaos by bringing everything you need into one centralized platform that works seamlessly across departments.

Whether your teams are in the office, on the warehouse floor, or working remotely, Kechie gives everyone real-time access to the data they need to do their jobs. And because it’s cloud-based and mobile-friendly, your entire operation becomes more flexible, connected, and efficient.

For many of our clients, switching to Kechie meant no more double entry, no more data syncing between platforms, and no more confusion over who has the most up-to-date information. Just one powerful system that manages your business from end to end.

“Being a cloud-based software, we are able to use this from anywhere and on any mobile device. Very easy to navigate and a well-thought-out program that caters to all aspects of a business.”

– Operations, Manufacturer and Distributor

“Kechie is the foundation of everything that we do. From integrating our eCommerce sites and B2B portal with our unique back-end processes to managing all aspects of our bookkeeping, customer service, CRM, procurement, warehouse operations, shipping and receiving—Kechie was built around the way we do business, not the other way around. I never imagined one system could manage nearly every aspect of our business.”

– COO, Consumer Goods Company

Ready to See Why So Many Businesses Choose Kechie ERP?

Our mission is simple: empower growing businesses with the tools they need to scale smarter, faster, and with less friction. From day one, we work as your partner—not just your software provider.

If you're looking for an ERP that’s user-friendly, backed by world-class support, built to solve real problems, and delivers exceptional value—Kechie ERP might be the perfect fit.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of an ERP.

Why Now Is the Time to Transition to QuickBooks Online or an Integrated ERP

QuickBooks Desktop 2022 Is Sunsetting: Why Now Is the Time to Transition to QuickBooks Online or an Integrated ERP

If your business is still using QuickBooks Desktop 2022, time is running out. As of May 31, 2025, Intuit will end support for this version, including access to payroll, payments, bank feeds, and critical updates. Businesses need to migrate now — but to where?

While QuickBooks Online is an option, many businesses are choosing to leap forward with a modern ERP system. The good news: Kechie ERP offers a flexible path — whether you want to sync with QuickBooks Online or move to a fully integrated ERP with complete accounting and operational features.

Why QuickBooks Desktop 2022 Is Ending — and Why It Matters

Intuit is focusing on cloud-based solutions, which means QuickBooks Desktop 2022 users will soon lose:

- Payroll and payment processing

- Online banking functionality

- Security updates and customer support

- Access to key features and integrations

Delaying your migration could risk lost functionality, compliance issues, and data security vulnerabilities.

Kechie ERP Offers Both Migration Paths

Whether you're ready for a full digital transformation or prefer to keep QuickBooks Online for accounting, Kechie ERP gives you both options:

✅ Sync with QuickBooks Online

- Bi-directional integration

- Sync customers, vendors, invoices, and purchase orders

- Centralize operations in ERP without giving up QBO

✅ Fully Integrated ERP with Built-In Accounting

- Eliminate the need for multiple systems

- Gain real-time visibility into finances, inventory, and sales

- Automate workflows across departments

Go Beyond Accounting: Kechie ERP’s Operational Power

Where QuickBooks stops, Kechie ERP begins. Designed for growing manufacturers, distributors, and nonprofits, Kechie ERP delivers powerful features that streamline operations from end to end.

✔ Advanced Inventory Management

- Real-time inventory tracking across multiple locations

- Support for standard, bundled, serialized, and lot-tracked items

- Reorder points and demand forecasting

- Barcode scanning and mobile inventory control

✔ Serialization & Lot Tracking

- Full traceability for serialized and lot-controlled inventory

- Easily comply with industry regulations (FDA, ISO, etc.)

- Simplify recalls, warranty tracking, and quality control

✔ Streamlined Purchasing and Sales

- Convert sales orders into POs with one click

- Supplier portals for quoting and direct ordering

- Automated backorder handling and fulfillment

✔ Manufacturing and Assembly

- Track raw materials and finished goods

- Bill of Materials (BOM) and production planning

- Cost roll-ups and work-in-progress visibility

✔ Real-Time Reporting and Dashboards

- Custom financial and operational reports

- Role-based dashboards with drill-down capability

- Audit trails and compliance-ready reporting

With Kechie ERP, your operations, accounting, and inventory all work together — not in silos.

Don’t Wait to Plan Your Move

The sunsetting of QuickBooks Desktop 2022 isn’t just a software update — it’s a business decision. Start preparing now by:

- Auditing your current processes and pain points

- Deciding whether to stay with QBO or upgrade fully

- Connecting with a migration expert or ERP provider

Kechie ERP Makes Your Transition Easy

Kechie ERP is purpose-built for growing organizations that need more than just accounting. Whether you want to extend your use of QuickBooks Online or fully transition to a modern, integrated system, we’ll help you get there — without disruption.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of an ERP.

What Is Task Management Software

What Is Task Management Software? Why It’s Even Better Inside Your ERP

If you’ve ever juggled sticky notes, spreadsheets, and endless email chains just to stay on top of your to-do list at work—you're not alone. Managing tasks can quickly become overwhelming, especially as your business grows and your team spreads across departments.

That’s where task management software comes in. But here’s the thing: using it as a standalone tool is helpful, sure—but when it’s built right into your ERP system, that’s when the real magic happens.

Let’s break it down.

What Exactly Is Task Management Software?

At its core, task management software helps you and your team stay organized. You can assign tasks, set deadlines, track progress, and collaborate more easily. Most platforms come with features like:

- Assigning responsibilities

- Setting due dates and priorities

- Tracking progress in real time

- Team collaboration tools

- Notifications to keep everyone in the loop

Think of it as a digital command center for getting things done.

Now, Here’s Why It’s Better Inside an ERP

ERP (Enterprise Resource Planning) software connects all the moving parts of your business—inventory, purchasing, finance, sales, operations—into one system. When your task management tools are part of that same system, things just flow better.

Here’s why:

1. Everything’s in One Place

No more bouncing between apps. Assign and manage all your tasks and deadline in one place.

2. Better Team Collaboration

Everyone—from the warehouse to the finance team—can stay in sync. Tasks tied directly to real-time data make it easier for teams to work together without confusion or delays.

3. More Accountability (Without Micromanaging)

You can see who’s working on what and how things are moving along. It’s easier to follow up, and team members know exactly what’s expected of them.

4. Fewer Delays and Surprises

Automated updates and reminders mean fewer dropped balls. Teams stay on track without needing to chase down information or updates.

5. Smarter Decisions, Faster

Because tasks are tied to live ERP data, like inventory levels or sales orders, your team can make better, faster decisions without guessing.

6. It Grows With You

As your business scales, your task management needs get more complex. A task manager inside your ERP is flexible enough to handle custom workflows and bigger teams without needing a separate tool.

Final Thoughts

Task management software is great. But task management inside your ERP? That’s a game changer. It helps your team work smarter, not harder—keeping projects on track and making sure nothing falls through the cracks.

If your ERP system doesn’t have this kind of functionality—or if your team is still using disconnected tools—it might be time to consider a more integrated solution like Kechie ERP, which brings task tracking, business workflows, and real-time data together in one place.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices and business workflows!

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of an ERP.

A Complete Guide to Migrating to ERP from QuickBooks

Outgrowing QuickBooks? A Complete Guide to Migrating to ERP

This guide will walk you through what QuickBooks users need to know before migrating to an ERP system — including what QuickBooks lacks, how to prepare, which pitfalls to avoid, and how to calculate the ROI of your move.

Why QuickBooks Users Outgrow the Platform

QuickBooks is excellent for startups and small businesses that need basic accounting. But as your operations expand, you begin to feel the limitations. Here are the most critical functionalities missing in QuickBooks that signal it’s time for a more robust solution:

1. No Chart of Accounts Numbers

QuickBooks doesn’t natively support account numbers, making it hard to structure financial reports or track segmented financials across departments or business units.

2. Limited Inventory Management

QuickBooks lacks:

-

-

- Real-time inventory visibility across multiple locations

- Lot and serial number tracking

- Bills of materials (BOMs)

- Support for kits, bundles, and assemblies

-

3. No True Multi-Entity or Multi-Location Management

If you operate in multiple states or countries — or have multiple business entities — QuickBooks doesn’t offer native consolidated reporting or intercompany workflows.

4. Lack of Custom Workflows & Automation

Tasks like approvals, recurring billing, or inventory reordering must be handled manually or with clunky workarounds.

5. Weak Permission Controls

QuickBooks doesn’t provide robust role-based access controls, making it harder to manage internal security or enforce audit trails.

6. No Integrated CRM or Order Management

CRM, quote-to-order, or customer lifecycle tools need to be added separately — often creating disconnected systems and inconsistent data.

7. Scalability and Performance Issues

Larger transaction volumes or multi-user access often slow the system, and QuickBooks Online’s limitations become apparent quickly.

How to Prepare for ERP Migration: A Step-by-Step Guide

Moving to an ERP is a big step, but a well-planned migration makes all the difference. Here’s how to approach it:

Step 1: Assess Your Business Requirements

Start by listing:

- What’s not working in QuickBooks?

- What functionality do you need in your next system?

- Which departments will use the ERP?

- How do you want reporting, inventory, purchasing, and CRM to work together?

🧠 Pro Tip: Involve stakeholders from finance, operations, sales, and warehouse teams in this conversation — each will have different needs and frustrations to address.

Step 2: Choose the Right ERP

Look for:

- Industry-specific functionality

- Cloud-native flexibility

- Modular growth (start with core accounting, add inventory, CRM, etc.)

- A strong onboarding and support track record

💡 Consider ERP systems like Kechie ERP, which offer powerful financials, integrated inventory and CRM, and built-in best practices — ideal for QuickBooks users ready to scale.

Step 3: Clean and Map Your Data

Migration is only as good as the data you bring with you. Start by:

- Cleaning up your Chart of Accounts

- Removing duplicate or inactive vendors, customers, and SKUs

- Mapping QuickBooks fields to your ERP (e.g., Inventory GL account → ERP GL code 1400)

- Standardizing formats for addresses, SKUs, and naming conventions

📌 Be sure to add account numbers to your Chart of Accounts — ERPs rely on structured numbering for segmentation, reporting, and hierarchy.

Step 4: Redesign Your Workflows

Don’t replicate QuickBooks in your ERP — improve your processes.

Common ERP workflow enhancements:

- Automate purchase order generation based on stock levels

- Add multi-stage invoice approvals

- Connect sales orders to fulfillment and invoicing

- Streamline receiving and inventory updates

🛠️ Use the ERP’s capabilities to automate where QuickBooks forced manual steps.

Step 5: Configure and Customize Thoughtfully

Your implementation partner will help you:

- Set up your COA with account numbers and segments

- Create roles, permissions, and access controls

- Define tax rules, shipping methods, and terms

- Build dashboards for real-time business insight

🚫 Don’t over-customize too soon — start with standard configurations and adapt as needed.

Step 6: Run a Pilot and Go Live in Phases

Avoid a “big bang” approach. Instead:

- Test a subset of live data (1 month’s worth) in a sandbox

- Validate financials and transaction flows

- Train users on a limited scope

- Go live in phases — starting with accounting, then inventory, CRM, and more

Step 7: Train Your Team and Support Change

A successful ERP rollout depends on user adoption.

Training tips:

- Offer role-specific training sessions

- Record how-to videos and create quick reference guides

- Assign “ERP champions” in each department

- Create a feedback loop to handle issues quickly

What to Avoid During Migration

- Migrating outdated or incorrect data

- Failing to define ownership for each functional area

- Ignoring user training and change management

- Over-customizing before you understand standard ERP features

What ROI Can You Expect?

A modern ERP helps you:

✅ Reduce manual data entry and errors

✅ Improve inventory accuracy

✅ Increase order fulfillment speed

✅ Make better business decisions with real-time data

✅ Scale operations without changing systems again

Most businesses report a full return on investment within 12–24 months, depending on complexity.

Final Thoughts

QuickBooks is great — until it’s not. Once you need better inventory control, stronger financial structure, automation, and cross-functional visibility, it’s time for ERP.

Systems like Kechie ERP offer QuickBooks users a smarter, scalable next step, without the overwhelm. With the right planning, migration can be smooth, efficient, and incredibly rewarding.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of an ERP.

What is EDI?

What Does EDI Stand For and What Does It Do?

EDI, or Electronic Data Interchange, is the automated, electronic exchange of business documents between trading partners in a standardized format. This technology replaces traditional paper-based processes, allowing businesses to exchange information like purchase orders, invoices, and shipping notices seamlessly.

By using a predefined format, EDI ensures that data is transmitted in a way that both parties can easily interpret and integrate into their systems, fostering accuracy and efficiency.

What is the difference between EDI and traditional method?

- With traditional invoicing, a seller has to create and deliver a physical invoice to the buyer, either via mail or in person.

- EDI invoicing involves the digital, near-instantaneous sending and receipt of an electronic invoice using a standardized format via a secure network.

How Does EDI Work?

EDI eliminates the need for manual data entry and ensures documents are delivered faster and with fewer errors. Here’s how it works:

1. Document Preparation: Data is extracted from the sender’s internal system, such as an ERP or inventory management software.

2. Translation: The data is converted into a standardized EDI format, such as ANSI X12 or EDIFACT, using EDI software.

3. Transmission: The formatted EDI document is securely transmitted to the recipient using protocols like AS2, FTP, or VAN.

4. Integration: The recipient’s system automatically interprets the data, integrating it into their processes, such as inventory updates or invoice reconciliation.

Key Benefits of EDI

1. Speed: EDI transactions are completed in seconds or minutes, much faster than traditional methods.

2. Accuracy: Automation reduces manual errors, such as typos or lost paperwork.

3. Cost Savings: By reducing paper use and manual processes, businesses save on administrative and operational costs.

4. Improved Relationships: Faster, error-free transactions lead to stronger supplier and customer relationships.

5. Scalability: EDI makes it easier for businesses to handle increased transaction volumes without additional staff.

Common Uses of EDI in Business

-

- Retail: Large retailers use EDI for purchase orders, invoices, and inventory updates.

- Manufacturing: Manufacturers rely on EDI for order confirmations, shipping schedules, and production forecasts.

- Logistics: Carriers use EDI to exchange shipment tracking information and delivery confirmations.

EDI in Modern ERP Systems

Integrating EDI with an ERP system like Kechie ERP takes its benefits to the next level. By automating the data exchange process directly within the ERP platform, businesses can further streamline operations. For example, Kechie ERP ensures that incoming EDI transactions are immediately processed, updating inventory and triggering automated workflows.

This level of automation reduces administrative tasks, enhances decision-making, and provides real-time visibility into your operations.

Conclusion

EDI is a powerful tool for modern businesses, enabling faster, more accurate, and cost-effective communication with trading partners. By leveraging EDI, companies can eliminate inefficiencies, improve relationships, and position themselves for growth in an increasingly digital world.

Connect with us today, our expert team is here to guide you through the process and help you discover the transformative potential of our solutions.

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of ERP.

How Kechie ERP Software Transforms Operations Across Key Business Sectors

How Kechie ERP Software Transforms Operations Across Key Business Sectors

Kechie ERP supports diverse business sectors, enhancing efficiency and growth.

Kechie ERP is an all-in-one software solution that can be customized to meet the unique needs of distributors, manufacturers, and service-based businesses. Whether you're managing supply chains, overseeing production processes, or handling customer service operations, Kechie ERP simplifies day-to-day tasks to boost efficiency. But before we dive into how these businesses leverage Kechie ERP, let’s take a closer look at how companies in these sectors can manage their operations more effectively with this powerful tool.

Distributors: Streamlining Operations with Kechie ERP

Distributors need a reliable system to manage inventory, logistics, and customer relationships—tasks that are often manual, time-consuming, and prone to error. Kechie ERP’s automation eliminates the need for repetitive tasks, making the entire distribution process more efficient. For instance, if you’re rushing to create a sales order but don't have time to generate invoices and packing slips, Kechie ERP takes care of it automatically. As soon as the sales order is entered and shipped, both the invoice and packing slip are generated. Additionally, Kechie ERP features a B2B portal that allows wholesalers to view available merchandise in your warehouse and make purchases—streamlining order management and communication.

With Kechie ERP, distribution companies can efficiently track orders, optimize their supply chains, and maintain excellent customer service, all from CRM to procurement, logistics, order management, returns, and financials. It truly covers it all.

Key Features for Distributors:

● Automated Order Processing: Automatically generates invoices and packing slips, reducing manual effort and errors.

● B2B Portal: Seamlessly share inventory availability with retailers and wholesalers for easier order management.

● Demand Forecasting & Replenishment: Use data-driven insights to optimize inventory levels and avoid stockouts or overstocking.

● Multi-Channel Order Management: Manage orders from various sales channels, including e-commerce platforms, marketplaces, and retail locations.

● Returns & Reverse Logistics: Simplify returns processing and maintain customer satisfaction.

● Supplier & Vendor Management: Automate purchase orders, track vendor performance with scorecards, and enable real-time collaboration with suppliers.

● Warehouse Management System (WMS): Optimize storage, picking, and shipping processes for better fulfillment efficiency.

● EDI Integration: Ensure seamless electronic data interchange with suppliers and customers.

● Automated Pricing & Discounts: Easily manage tiered pricing, bulk discounts, and promotional pricing rules.

● Fleet & Delivery Management: Improve last-mile delivery efficiency with real-time tracking.

● Financial Reporting & Cash Management: Gain real-time financial insights, improve cash flow management, and streamline accounting for better profitability.

Manufacturers: Simplifying Complex Workflows

Manufacturers face intricate workflows, supply chain management challenges, and the constant need for rigorous quality control. Kechie ERP integrates these functions into a single system, automating essential tasks, tracking production progress, and maintaining quality standards throughout the production cycle. Kechie supports flexibility in production jobs without sacrificing accuracy, while also offering full audit traceability for all materials and processes, from start to finish.

So, how does Kechie ERP streamline manufacturing workflows? By consolidating key processes such as scheduling, task management, and quality control, the software ensures manufacturers can track every step of the production process. With full audit visibility, manufacturers can improve production schedules, enhance inventory management, and stay compliant with industry standards—all while reducing manual tasks and improving operational efficiency.

Key Features for Manufacturers:

● Material Requirements Planning (MRP): Optimize raw material procurement and align inventory with production schedules.

● Bill of Materials (BOM) Management: Track and manage multi-level BOMs to efficiently oversee product assembly.

● Production Scheduling & Capacity Planning: Allocate resources effectively to minimize downtime and ensure seamless production.

● Shop Floor Control: Real-time tracking of work orders, labor, machine usage, and production efficiency.

● Quality Control & Compliance: Implement inspections, enforce regulatory standards, and keep audit-ready compliance records.

● Traceability & Lot/Serial Tracking: Maintain full transparency from raw materials to finished goods with complete traceability.

● External Manufacturing Management: Track outsourced production and ensure external suppliers meet quality standards.

● Automated Workflows: Streamline approval processes, production workflows, and compliance reporting.

● Cost Tracking & Variance Analysis: Monitor cost fluctuations and profitability throughout the production cycle.

● Financial Reporting: Optimize financial oversight and track key performance indicators (KPIs) for smarter decision-making.

Service-Based Companies: Enhancing Flexibility and Efficiency

Service-based businesses—whether in consulting, education, or maintenance—require flexible tools to schedule appointments, manage projects, and maintain strong client relationships. Kechie ERP enables service companies to enhance these capabilities by providing robust tools for task management, time tracking, equipment maintenance, and customer relationship management.

For example, service technicians out in the field can create a work order right from their phone. Once the task is completed, stock levels automatically adjust in real time, and customers are instantly billed (if their financial details are on file). Kechie ERP also ensures PCI-compliant, tokenized transactions through its accounting module. For companies providing long-term services, Kechie ERP supports deferred revenue recognition, ensuring that revenue is accurately recognized over the course of a service contract. This guarantees compliance and accurate financial reporting.

Key Features for Service Companies:

● Work Order Management: Create and manage work orders in real-time, track job status, and automate billing.

● Field Service Management: Enable technicians to update job statuses, access service history, and process payments via mobile devices.

● Time & Expense Tracking: Log billable hours and expenses with ease for client projects.

● Deferred Revenue Recognition: Automate the recognition of revenue for long-term contracts, ensuring financial accuracy and compliance.

● Contract Management: Track service agreements, automate renewals, and ensure compliance with client SLAs.

● Customer Relationship Management (CRM): Foster better customer relationships with automated follow-ups, personalized interactions, and centralized customer data.

● Appointment Scheduling & Dispatching: Optimize technician schedules and reduce unnecessary travel time.

● Recurring Billing & Subscription Management: Automate invoicing for ongoing contracts and subscription-based offerings.

● Project Costing & Budgeting: Keep a close eye on project profitability with real-time cost tracking.

● Financial Insights: Track KPIs, improve financial transparency, and drive business growth.

Kechie ERP provides the tools and automation necessary to streamline operations and boost efficiency, regardless of business type. Whether you're a distributor, manufacturer, or service provider, Kechie ERP is designed to meet your unique needs and support the growth of your business.

For more information on how Kechie ERP can transform operations within specific industries, be sure to check out our upcoming article detailing how our software helps companies across various industries thrive in their market.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of ERP.

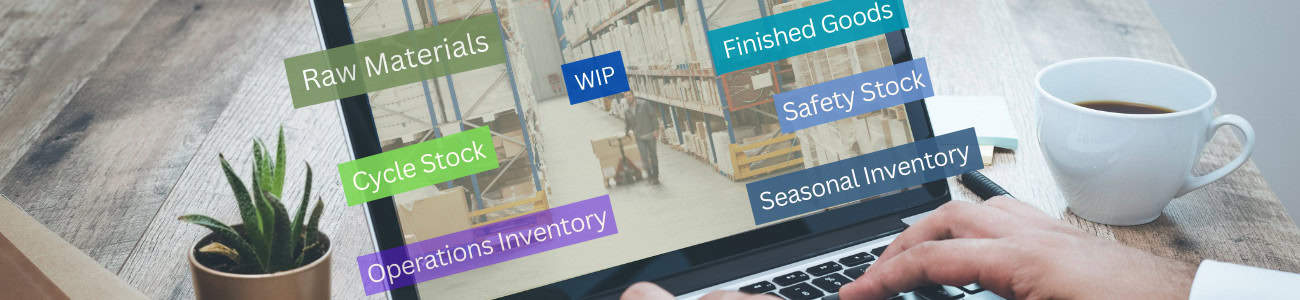

What is Inventory? A Comprehensive Guide to Types and Uses

What is Inventory? A Comprehensive Guide to Types and Uses

In this blog, we’ll explore what inventory is, the different types of inventory, how each type plays a vital role in various business operations, and the impact of inventory levels on financial and operational performance.

What is Inventory?

At its core, inventory encompasses all the tangible items that a company manages in its supply chain. These items can include raw materials, work-in-progress goods, finished products, and even consumables used in production. Properly managing inventory is essential for businesses to:

- Meet customer demand without delays.

- Reduce excess stock and associated carrying costs.

- Improve cash flow and operational efficiency.

- Respond quickly to market fluctuations or disruptions.

Inventory is not merely a static concept; it is dynamic and directly impacts multiple business processes, from procurement and production to sales and customer service.

Types of Inventory

Understanding the different types of inventory is crucial for optimizing business processes. Let’s break down the main categories:

1.Raw Materials

Raw materials are the basic components used in manufacturing or production processes. These are often purchased from suppliers and transformed into finished goods.

Examples: Steel for car manufacturing, flour for baking, or fabric for clothing production.

Uses:

-

- Essential for starting the production process.

- Stock levels must align with production schedules to avoid disruptions.

- Provides flexibility to respond to changes in production demand.

2.Work-in-Progress (WIP)

Work-in-progress inventory refers to items that are partially completed. These goods are in the process of being transformed from raw materials into finished products.

Examples: A car chassis on an assembly line or dough being prepared in a bakery.

Uses:

-

- Represents the intermediary stage of production.

- Managing WIP helps track production efficiency and identify bottlenecks.

- Reduces idle time in manufacturing by ensuring a continuous flow of goods.

3. Finished Goods

Finished goods are the final products that are ready for sale to customers. These items have completed the manufacturing process and meet quality standards.

Examples: Smartphones, packaged food, or furniture.

Uses:

-

- Directly impact revenue as these goods are sold to customers.

- Efficient turnover of finished goods is vital to maintain cash flow.

- Acts as a measure of demand forecasting accuracy.

4. Maintenance, Repair, and Operations (MRO) Inventory

MRO inventory includes items that are not directly part of the final product but are essential for keeping the business operations running smoothly.

Examples: Spare machine parts, cleaning supplies, or lubricants.

Uses:

-

- Ensures that equipment and facilities remain functional.

- Reduces downtime caused by equipment failure.

- Critical for maintaining operational continuity.

5. Safety Stock

Safety stock refers to extra inventory kept on hand to mitigate risks such as supply chain disruptions or unexpected spikes in demand.

Examples: Additional raw materials or finished goods stored as a buffer.

Uses:

-

- Acts as a safeguard against uncertainties.

- Helps maintain customer satisfaction by avoiding stockouts.

- Provides a cushion during supply chain disruptions or peak seasons.

6. Cycle Stock

Cycle stock is the portion of inventory regularly used to fulfill orders. It’s the stock that is cycled through in normal business operations.

Examples: Everyday items in retail stores or production materials for consistent demand.

Uses:

-

- Optimized based on order frequency and lead times.

- Reduces holding costs by minimizing overstocking.

- Aligns inventory turnover with operational efficiency goals.

7. Seasonal Inventory

Seasonal inventory includes goods stocked to meet seasonal demand, such as holiday products or summer clothing.

Examples: Christmas decorations or swimsuits.

Uses:

-

- Ensures businesses are prepared for peak demand periods.

- Requires accurate forecasting to prevent excess inventory.

- Helps capitalize on short-term market trends.

8. Consignment Inventory

Consignment inventory refers to stock that a supplier owns but stores at the buyer’s location until it is sold.

Examples: Branded apparel at retail stores.

Uses:

-

- Reduces upfront costs for buyers.

- Encourages suppliers to ensure their products sell quickly.

- Promotes collaboration between buyers and suppliers.

The Effect of Inventory on Your Business

Managing inventory levels effectively is a balancing act. The effects of inventory on your business can significantly influence both financial performance and operational success.

Effects of Inventory: Overstock and understock

Managing inventory levels effectively is crucial, as both overstock and stockout scenarios can significantly affect a business's financial and operational health. Below are the key impacts of not maintaining a balance in inventory:

Impacts of Overstock:

- Improved Customer Satisfaction: Overstock ensures products are readily available to meet customer demand.

- Reduced Risk of Stockouts: Having extra inventory minimizes disruptions in operations due to unavailable materials.

- Ability to Capitalize on Bulk Discounts: Purchasing large quantities can lead to cost savings from suppliers.

- Flexibility for Market Changes: A buffer stock allows businesses to respond quickly to unexpected demand surges or delays in supply.

- Challenges: However, overstock leads to increased carrying costs, risk of obsolescence (especially for seasonal or perishable items), tied-up capital that could be used elsewhere, and storage space constraints that can escalate operational costs.

Impacts of Stockout:

- Lower Holding Costs: Stockout reduces expenses related to storage and maintenance.

- Improved Cash Flow: With fewer resources tied up in inventory, businesses can allocate capital to other investments or needs.

- Minimized Risk of Obsolescence: Lean inventory reduces the likelihood of items becoming outdated or unsellable.

- Efficient Use of Space: Reducing inventory frees up valuable storage space for other operations.

- Challenges: On the downside, stockouts can lead to lost sales, damage customer trust, disrupt production, incur higher costs for urgent procurement, and erode brand loyalty as customers may turn to competitors.

Balancing inventory is not only about maintaining financial health but also about ensuring customer satisfaction and operational efficiency. Effective strategies and tools, such as an integrated ERP system with robust inventory management and CRM capabilities, can help businesses achieve optimal inventory levels, minimize risks, and maximize profitability.

- Stockouts and Lost Sales: Inability to meet customer demand can harm brand reputation and revenue.

- Production Delays: Insufficient raw materials or components can disrupt manufacturing processes and significantly impact production schedules.

- Higher Costs for Urgent Procurement: Expedited shipping or emergency orders to fulfill urgent needs can significantly increase procurement costs.

- Reduced Customer Loyalty: Frequent stockouts can erode customer trust and drive them to seek alternatives from competitors.

Conclusion

Inventory is the backbone of any supply chain, and understanding its types is essential for effective management. From raw materials to finished goods, each type serves a specific purpose and impacts different aspects of a business’s operations. Striking the right balance between too much and too little inventory is critical to achieving operational efficiency and maintaining financial health.

By leveraging modern tools like Kechie ERP, businesses can gain real-time insights, streamline inventory processes, and ensure they remain competitive in a fast-paced market.

Contact us today to learn more about how Kechie ERP can transform your inventory management practices!

Stay tuned for our series of insightful blogs—your roadmap to exploring the full potential of ERP.

What is Reverse Logistics? A Comprehensive Guide

What is Reverse Logistics? A Comprehensive Guide

Reverse logistics has become increasingly important as businesses strive for sustainability and improved customer satisfaction. Let's explore what it is and why it matters.

Understanding Reverse Logistics

Reverse logistics involves the movement and management of goods after their initial sale. It typically includes:

- Returns Management: Processing customer returns for refund, replacement, or repair.

- Recycling and Disposal: Ensuring end-of-life products are disposed of responsibly or recycled.

- Refurbishing and Reselling: Repairing and repackaging items for resale.

- Warranty Recovery: Managing defective products under warranty.

- Asset Recovery: Recovering value from unsold inventory or unused equipment.

These processes not only help businesses recapture value but also contribute to sustainability efforts by reducing waste.

Why is Reverse Logistics Important?

- Enhanced Customer Satisfaction: Seamless return and replacement processes improve customer loyalty and trust.

- Cost Savings: Streamlining the returns process lowers operational expenses and recovers value from returned items.

- Regulatory Compliance: Proper disposal and recycling can help businesses meet environmental regulations.

- Sustainability: Promoting eco-friendly practices aligns with corporate social responsibility goals and appeals to environmentally conscious consumers.

Challenges in Reverse Logistics

Despite its benefits, reverse logistics poses challenges, such as:

- Complex Processes: Managing multiple steps, from product inspection to restocking or recycling.

- High Costs: Transportation, repair, and disposal can be expensive.

- Inventory Tracking: Keeping track of returned or refurbished products can strain existing systems.

Investing in robust ERP software like Kechie ERP can help businesses streamline reverse logistics operations. Kechie Inventory Management System integrates with your supply chain to track returned goods, automate workflows, and optimize asset recovery.

How to Optimize Reverse Logistics

- Leverage Technology: Use ERP system like Kechie RMA to track and manage returns efficiently.

- Create Clear Policies: Transparent return and recycling policies simplify processes for customers and employees.

- Focus on Sustainability: Partner with recycling firms or refurbish products to reduce environmental impact.

- Analyze Data: Monitor return patterns to identify product quality issues or other trends.

The Future of Reverse Logistics

With the rise of e-commerce, reverse logistics—the process of handling product returns—is becoming more important than ever. Managing returns efficiently is no longer just about cutting costs; it’s about creating a better customer experience and building a stronger, more sustainable business.

Conclusion

Reverse logistics isn’t just about handling returns—it’s a strategic process that can drive significant business value. From enhancing sustainability to improving customer experiences, mastering reverse logistics is essential for modern businesses. With the advancements in automation, artificial intelligence, and data analytics, tools like Kechie ERP simplify the process, making it more accurate, efficient, and resource-friendly.

Connect with us today and let our expert team guide you through the process of discovering the transformative potential of our solutions.